Umphumela we-welding we-robot welding uthintwa yizici eziningi. Amakhasimende amaningi azohlangabezana nezinkinga ngaphezulu noma ngaphansi ngaphambi kokuba abe nekhono ekusebenziseni amarobhothi okushisela. Ngokuyinhloko, lezi zinkinga zibangelwa ukusebenza okungalungile noma izilungiselelo zerobhothi ezingalungile, futhi zingaxazululwa ngokulungiswa okufanele. Okulandelayo, umhleli uzokuthatha ukuthi uthathe ezinye izinkinga ezivame ukwenzeka ekusetshenzisweni kwamarobhothi we-Yunhua welding kanye nezixazululo ezihlobene.

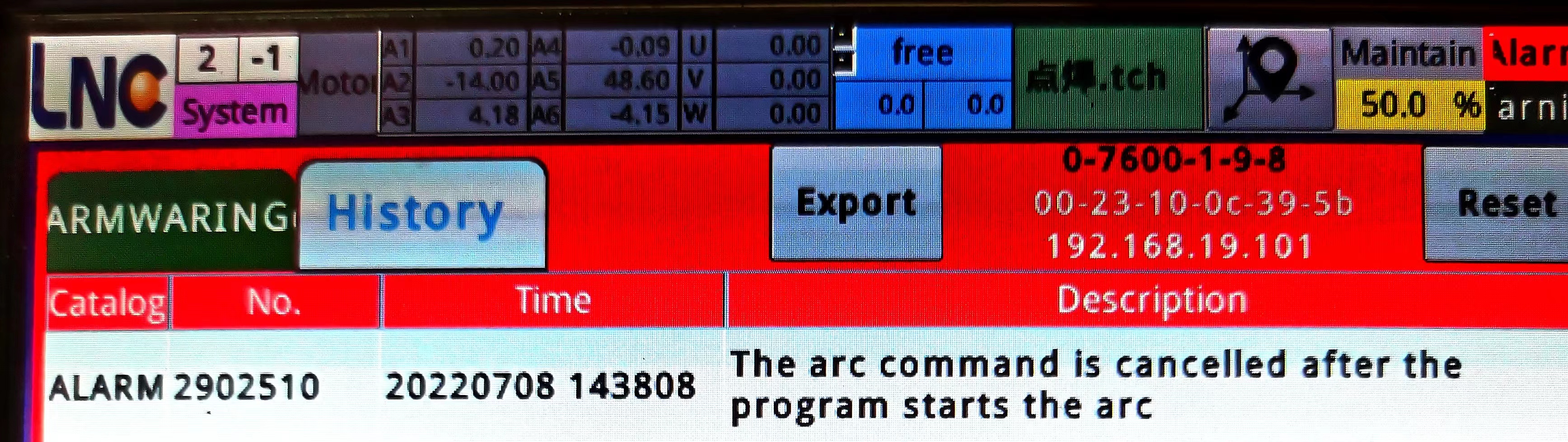

1. I-arc engaphumelelanga iqala ngesikhathi sokushisela

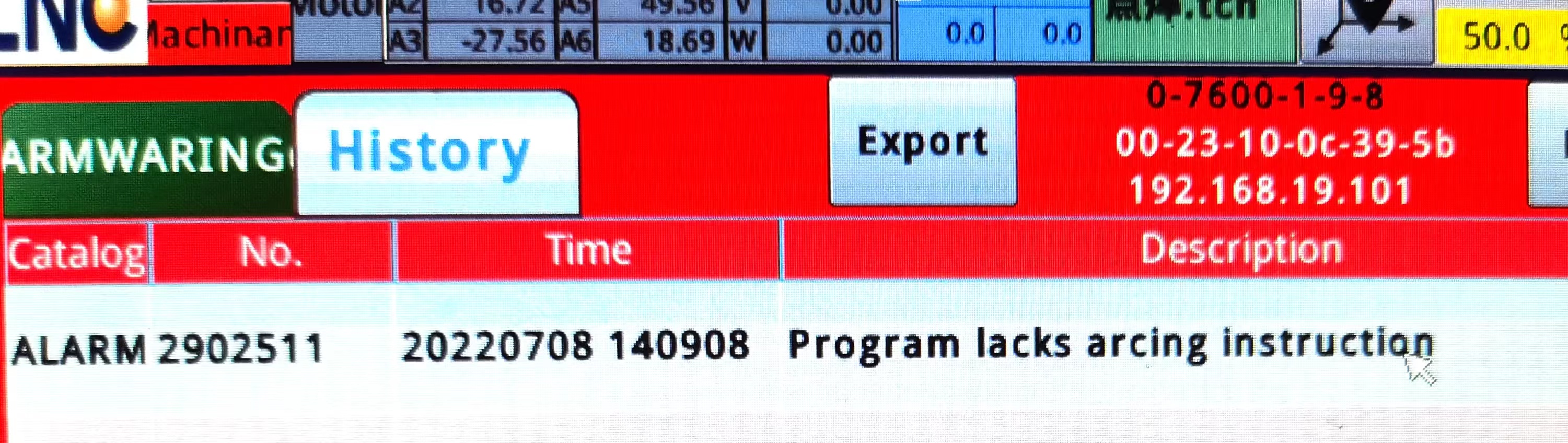

1. I-arc ayikaqali

Isizathu: Awukho umyalo wokuqala we-arc ohambisanayo ngaphambi kokufaka umyalo wokugcina we-arc ohlelweni oluhleliwe.

Indlela yokucubungula: Hlola ukuthi ungangeza umyalo owodwa wokugcina we-arc noma umyalo wokuqala we-arc owodwa omncane

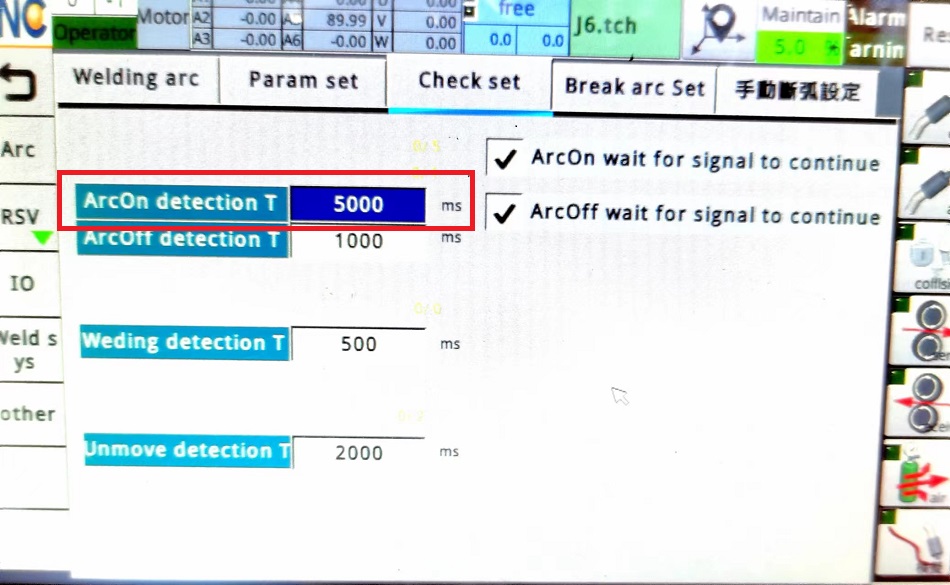

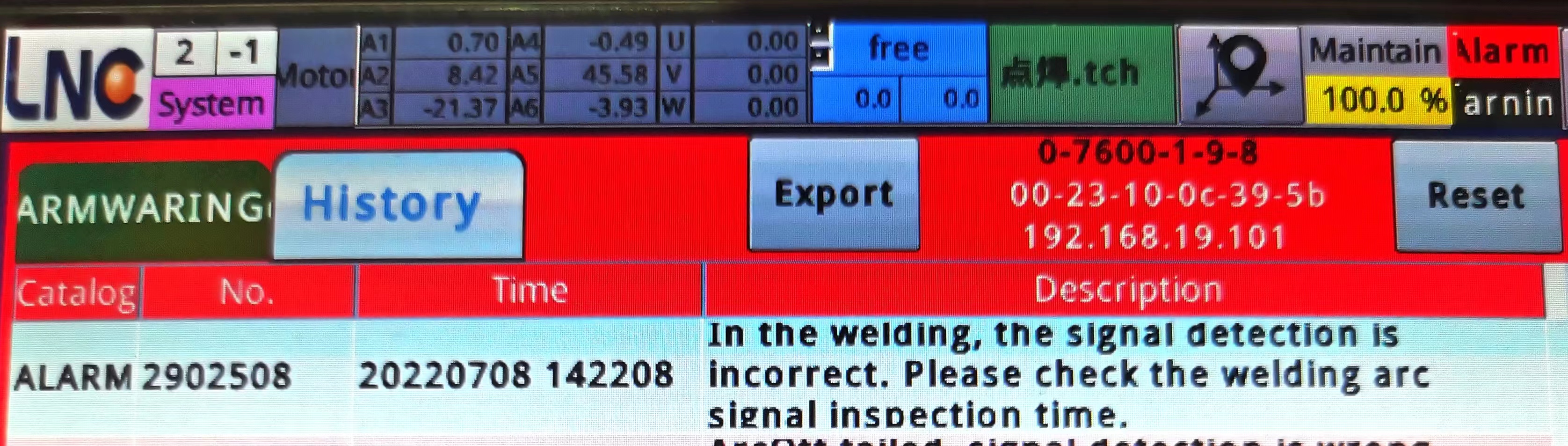

2. Yehlulekile ukuqalisa i-arc, ukutholwa kwesignali akulungile

3. I-Arc Fried Wire

isizathu:

1) Ukungafani kwamanje kanye ne-voltage

Indlela yokucubungula: Sidinga ukusetha i-current ne-voltage efanele ngokusho kobukhulu bangempela be-workpiece kanye nomshini wokushisela

2) Ubude bentambo yokushisela bude kakhulu

Indlela yokwelapha: Ngokuvamile, ubude bentambo yokushisela buyi-10 kuya kwezingu-15 ububanzi bocingo lokushisela, futhi ubude obufanele bocingo lokushisela bukhethwa ngokuvumelana nobubanzi bocingo lokushisela.

Umthamo omncane kakhulu uholela ekushiseleni okungalingani

I-current evamile kanye ne-voltage, i-weld enhle futhi eqinile

Ukuphela kwethoshi lokushisela kuzobhola ucingo

Intambo yethoshi yokushisela isesimweni esihle ngemva kokushisela okuvamile

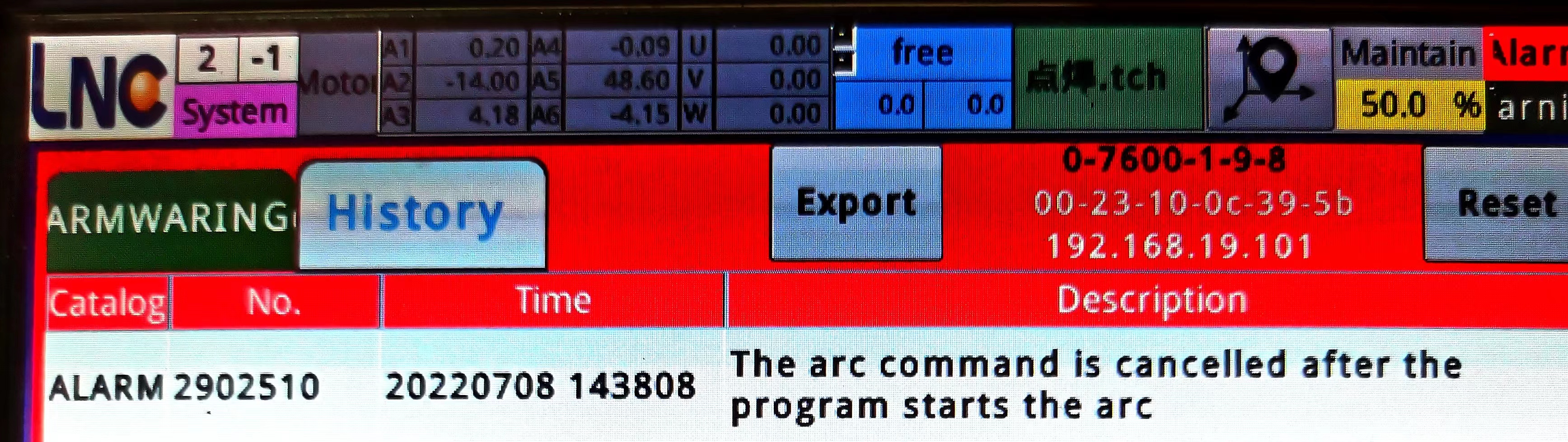

4. Isenzakalo sokucisha i-arc okuzenzakalelayo kwenzeka ngemva kwe-arcing

Isixazululo: Hlola ukuthi ingabe ikhona yini inkinga ngesikhathi sepharamitha esinganyakazi ukulungiselelwa kwesikhathi, futhi uhlole ukuthi ithoshi lokushisela lihambile yini.

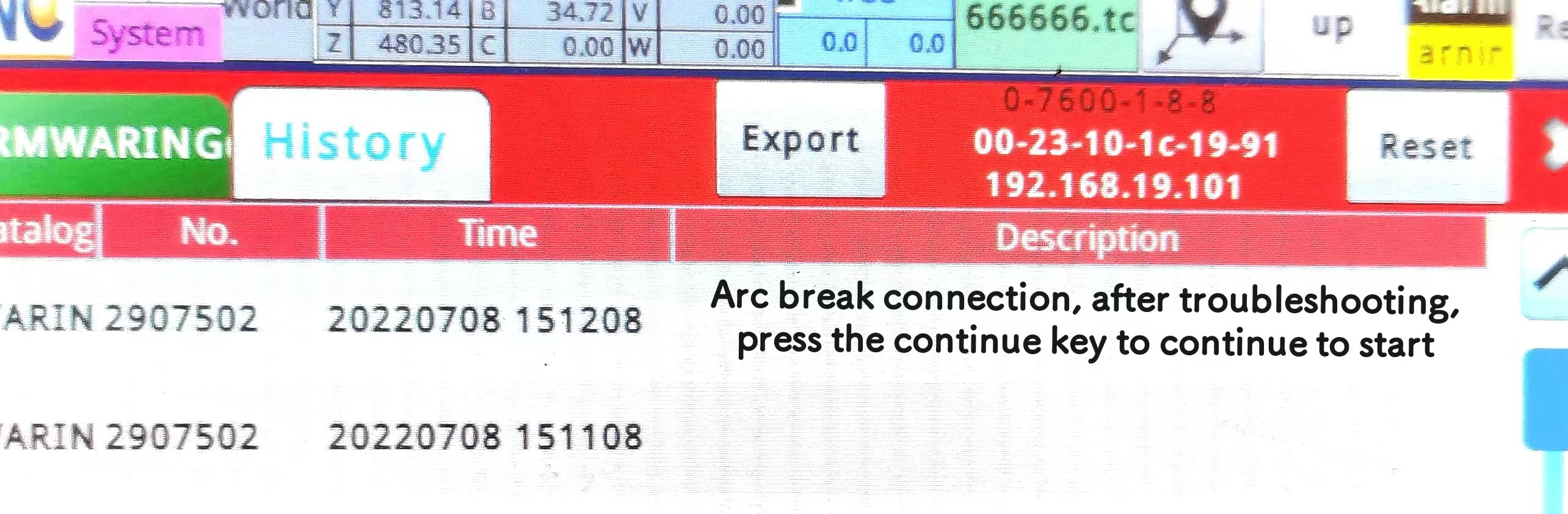

2. Ukuphuka kwe-arc kwenzeka ngesikhathi sokushisela

isizathu:

1. Uma ucingo lwe-welding lungathinti i-workpiece, i-arc breaking alarm izoqalwa

Indlela yokwelapha: Lungisa indawo yocingo lwe-welding kanye ne-workpiece, ukuze ucingo lokushisela luxhumane ngokugcwele nomsebenzi ngesikhathi senqubo yokushisela. (Kodwa akufanele isondele kakhulu ku-workpiece, ingaholela ekushiseleni ngocezu lokusebenza)

2. Indlela yokushisela engenangqondo ibangela ukuthi ikhanda lesibhamu liphakame ngokuzenzakalelayo ngenxa yokushayisana

Isixazululo: setha kabusha indlela yokushisela

3. Izintambo ezinhle nezimbi zomshini wokushisela azixhumene kahle

Indlela yokwelapha: Hlola isimo sezintambo zezintambo ezinhle nezingezinhle

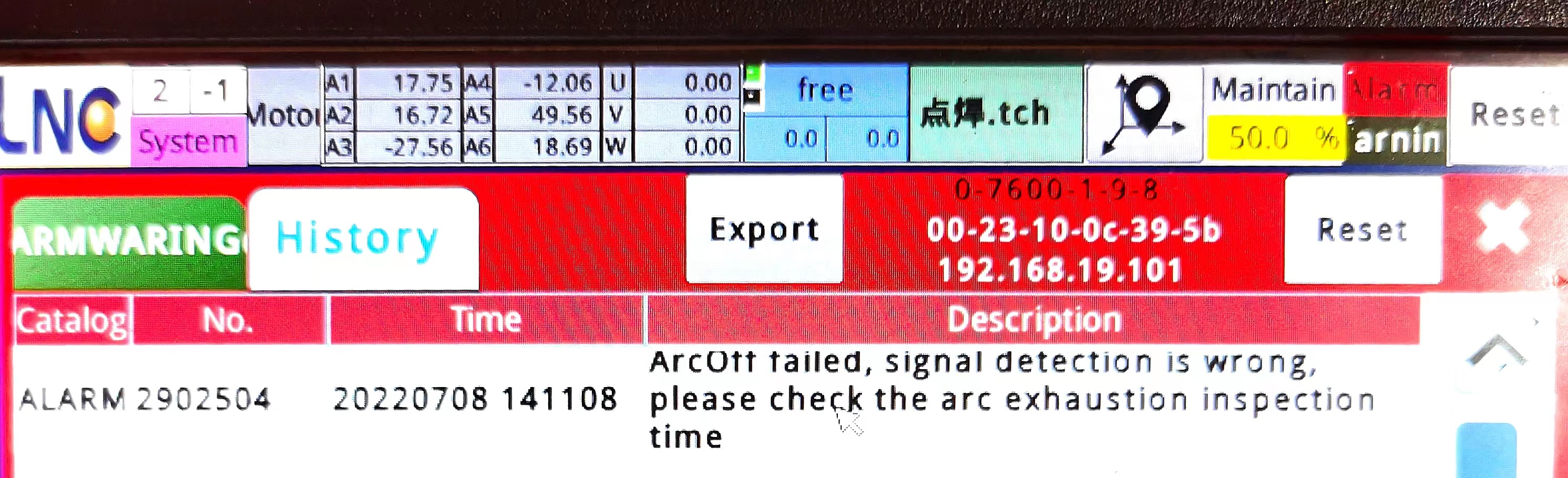

3. Izizathu zokungaphumeleli kokuphela kwe-arc ngemva kokushisela

1. Ukwehluleka kwe-arc, iphutha lokuthola isignali

Isizathu: Umshini wokushisela awuzange uthole isignali evela kurobhothi, okubangele ukuthi irobhothi lihluleke ukuvala i-arc.

Indlela:

(1) Hlola ukuthi amapharamitha wokusetha anengqondo yini

(2) Hlola isignali ye-IO, bese uhlola ukuthi isignali yendawo yokuqeda I ayijwayelekile yini. Uma isiginali ye-I point iqhubeka nokubonisa VULIWE.

(3) Hlola ukuthi ingabe kukhona isekethe emfushane emgqeni nokuthi ingabe intambo yaphansi ixhumeke ngokungavamile

2. Awukho umyalo wokumisa i-arc osethiwe ngemva kwesiteleka se-arc

Isizathu: Uma le alamu yenzeka ku-pendant yokufundisa, hlola ukuthi uyakhohlwa yini ukwengeza umyalo wokuphela kwe-arc

Indlela yokucubungula: engeza umyalo wokuphela kwe-arc ngemva komyalo wokuqala we-arc ohlelweni

Lolu daba lwethula ngokuyinhloko izinkinga ezihlobene ne-arc-starting, arc-breaking kanye ne-arc-ending yerobhothi le-Yunhua lokushisela ngesikhathi senqubo yokushisela. Uma abasebenzisi behlangabezana nezinkinga ezinjalo ngesikhathi sokusetshenziswa, bangabheka izixazululo. Uma zingaxazululeki, sicela ufune ochwepheshe base-Yunhua kusenesikhathi. Usizo.

Uma ufuna ukwazi izinkinga ezivamile nezisombululo ze-Yunhua Robot, sicela unake i-akhawunti esemthethweni ye-Yunhua Robot.

I-Yunhua welding irobhothi iyirobhothi elizenzakalelayo elihlanganisa ukushisela okunemisebenzi eminingi njengokushisela okuvikelekile kwegesi, i-argon arc welding, i-plasma cutting, ne-laser welding. Inokuguquguquka okuphezulu, ukuguquguquka okuqinile, ukusebenza kahle kwe-welding kanye nekhwalithi ye-welding ezinzile, futhi ingasetshenziswa kabanzi emikhakheni ehlukahlukene. Njengokukhiqiza imishini, ukukhiqizwa kwezimoto, ugesi oqondile kanye nezimayini zamalahle neminye imikhakha.

Isikhathi sokuthumela: Jul-15-2022