Ukukhiqizwa kwezimboni kuyisixhumanisi esibalulekile sokuthuthukisa umnotho nezenhlalakahle. Njengamanje, ucwaningo lwemishini yokushisela okuzenzakalelayo luyajula futhi lukhonkolo, okwenza lusetshenziswe kabanzi ekukhiqizeni izinhlobo ezahlukene zezakhiwo zokushisela.

In the inqubo Welding othomathikhi, ezihlakaniphile futhi digital control okunengqondo of Welding iphutha umhlangano igebe ngezinga elithile, ngalesi sisekelo, futhi umehluko workpiece isikhundla, workpiece ukuchezuka ngokuhlanganyela kanye nezinye izici okufanele zicatshangelwe. Ngakho-ke, ubuchwepheshe bokulandelela i-laser welding seam budlala indima ebalulekile enqubweni yokushisela.

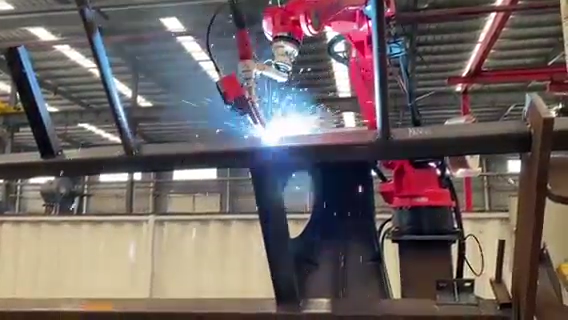

Ithangi lemoto likasimende lokushisela imoto eyi-Seven axis Earth orbit eyisishiyagalombili ejikelezayo ene-laser welding

-Indawo yokusebenzela iyahlukahluka kakhulu

-Ukuchezuka kukhona ekuxhumekeni kwe-workpiece

-Ukunemba okuphezulu kwe-welding kuyadingeka

-Indawo yokushisela empofu kanye nentuthu

Kulokhu, irobhothi elihlakaniphile le-Yooheart i-HY1006A-145 lisetshenziselwa ukushisela nge-laser welding seam tracking system, enokuguquguquka okuphezulu, ukuzinza nokuthembeka.

Ngaphambi kokushisela ngakunye, okokusebenza kuqala kuskena futhi kuqophe ukudidiyelwa komthungo wokushisela ngokusebenzisa indawo yokushisela, bese ibala i-coordinate offset nge-algorithm yangaphakathi bese ibeka imingcele yokuxhumanisa ireferensi esikhathini sangempela ukuze kulungiswe ukuchezuka kwangempela ngesikhathi, ukuze kuqinisekiswe ukuvala nobuqotho bomkhiqizo ngemva kokushisela.

Indlela "yempambano-mgwaqo yamaphuzu amane".

Njengoba kwaziwa kubo bonke, amaphuzu amabili anquma umugqa oqondile, kodwa umhlangano we-workpiece uzokwakha i-Angle, i-algorithm evamile ayikwazi ukunquma indawo yayo, lokhu kudinga ukusebenzisa indlela "yempambanomgwaqo" ngehora lesine, imigqa emibili ephambanayo ikhiqiza iphuzu le-intersection, i-algorithm ye-algorithm ekhethekile ngokunqunywa kwamaphuzu amane aziwayo izixhumanisi ezibalwe isikhundla senhloso yokuxhumanisa ukuze kuzuzwe iphuzu lokuxhumanisa.

Uhlelo lokulandela umphetho we-laser

Uhlelo lokulandela umthungo we-laser welding ikakhulukazi lwakhiwe izinzwa ze-laser namatheminali okuqapha. Inzwa ye-laser isetshenziselwa ukutholwa okusebenzayo kanye nokucubungula ngesikhathi sangempela solwazi lwe-welding seam, futhi igcina ukuxhumana kwesikhathi sangempela namarobhothi ezimboni. Itheminali yokuqapha Ihlola futhi ilungiselela izinzwa. Uhlelo luphinde lube nemisebenzi yokuthola, ukulandelela kanye nokuskena ngaphambi kokushisela ukuze kuhlangatshezwane nezidingo zokushisela okuhlakaniphile.

Umgomo wokusebenza: Ukuskena komthungo we-Weld, ukulingana kwesithombe sephoyinti, i-algorithm ikhomba ngokunembile amaphuzu esici, kanye nedatha yesikhathi sangempela yemiphumela yokubala ethunyelwa irobhothi, emiyalweni yokulawula, lungisa noma iqondise ukusebenza kwerobhothi.

Isixazululo sepuleti likathayela

Isixazululo sokushisela ipulaki eyisiyingi esiyindilinga

Isixazululo se-seam esiyindilinga

Izixazululo ze-tubeplate

I-Yunhua Intelligent inganikeza ukuthunyelwa okusheshayo, izixazululo ezizenzakalelayo eziphephile nezisebenzayo kanye nezixazululo zesistimu yesikhathi sangempela.Isistimu yokulandelela i-laser vision welding seam yenza irobhothi elishiselayo likwazi ukubona indawo yesikhathi sangempela sokuthungatha indawo kanye nokulandelela, futhi lilungise indlela yokushisela ngokusho kwe-welding seam offset enqubweni yokushisela, ukuze ibone ukuthi sihlakaniphile ngempela.

Isikhathi sokuthumela: Apr-09-2022