Isingeniso

Imboni yezimoto kudala iyingqalabutho ekwamukeleni ubuchwepheshe obusezingeni eliphezulu ukuze kuthuthukiswe ukusebenza kahle, ukunemba, kanye nokukaleka. Phakathi kwezingxenye zayo ezibaluleke kakhulu uhlaka lwemoto-umgogodla wesakhiwo oqinisekisa ukuphepha, ukuqina, nokusebenza. Njengoba izimfuno zezinto ezingasindi, ukwenziwa ngokwezifiso, kanye nokukhiqizwa ngokushesha kwanda, abakhiqizi baya ngokuya bephendukela kumarobhothi ezimboni ukuze baguqule ukwakhiwa kohlaka. Lesi sihloko sihlola ukuthi amarobhothi alungisa kanjani kabusha ukukhiqizwa kwamafreyimu ezimoto, kusukela ekuphathweni kwezinto ezibonakalayo kuya ekushiseleni nasekulawuleni ikhwalithi, kuyilapho kubhekwana nezinselelo namathrendi esikhathi esizayo kulo mkhakha onamandla.

Isigaba 1: Iqhaza Elibalulekile Lezinhlaka Zezimoto Ekwakhekeni Kwezimoto

Ozimele bezimoto, abavame ukubizwa ngokuthi i-chassis, basebenza njengesisekelo sawo wonke amasistimu ezimoto. Kumelwe bamelane nokucindezeleka okukhulu, babambe imithelela yokushayisana, futhi basekele isisindo semoto nabakuyo. Ozimele besimanje bakhiwe kusetshenziswa izinto ezithuthukisiwe ezifana nensimbi yokuqina okuphezulu, ama-alloys e-aluminium, kanye nezinhlanganisela ze-carbon fiber ukuze kulinganiswe amandla nokunciphisa isisindo.

Nokho, ukukhiqiza lezi zakhiwo eziyinkimbinkimbi kudinga ukunemba okwedlulele. Ngisho nokuchezuka okuncane ekuqondaneni kwe-welding noma ukuhlanganiswa kwengxenye kungalimaza ukuphepha nokusebenza. Izinqubo zezandla zendabuko ziyazabalaza ukuhlangabezana nokubekezelela okuqinile okufunwa izindinganiso zanamuhla zezimoto, okudala isidingo esicindezelayo sokuzenzakalela.

Isigaba 2: Amarobhothi Ezimboni Ekwenziweni Kohlaka: Izicelo Ezibalulekile

2.1 Ukuphathwa Kwempahla kanye Nokulungiselela Ingxenye

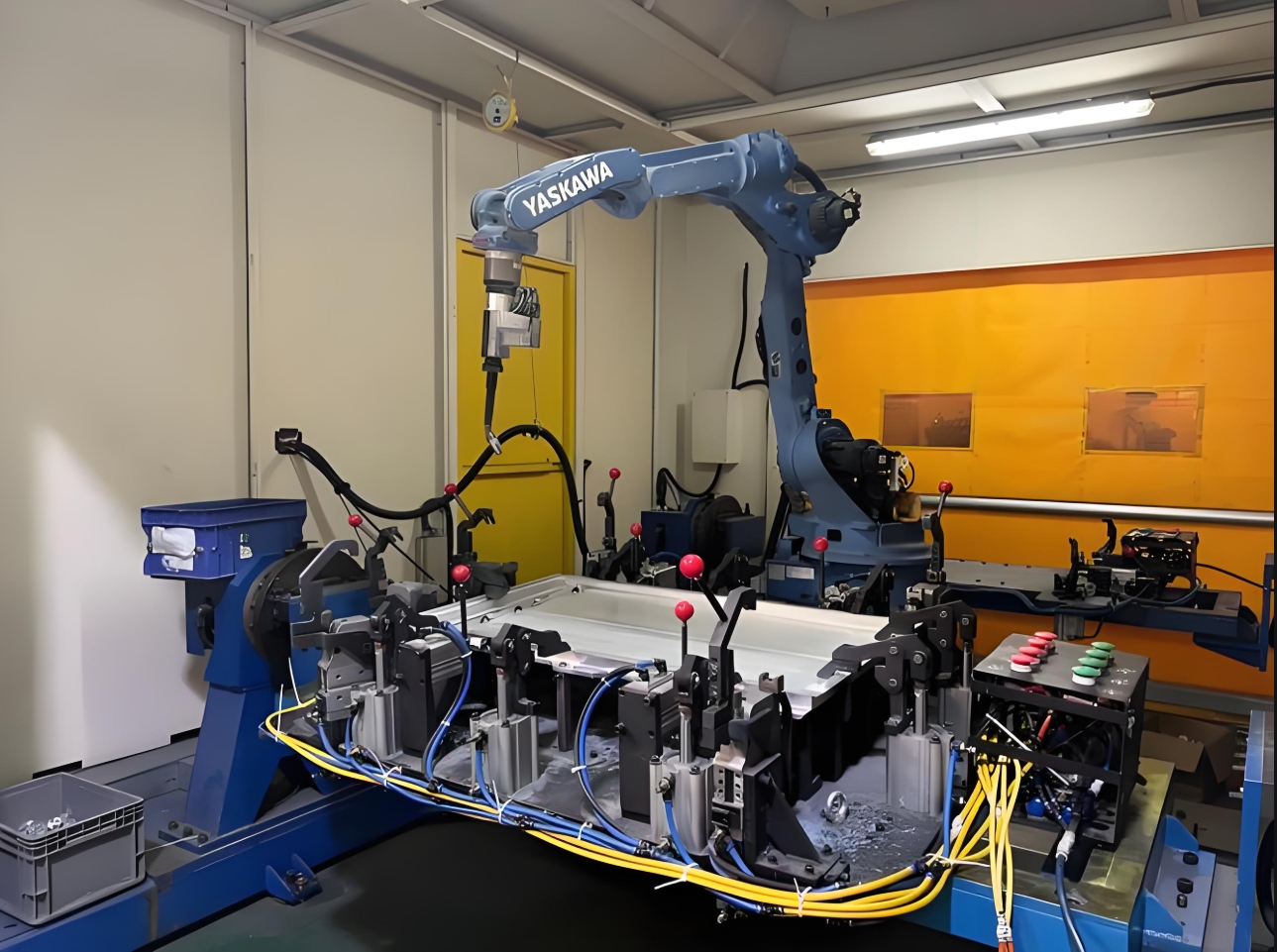

Ukukhiqizwa kozimele bezimoto kuqala ngokucubungula impahla eluhlaza. Amarobhothi ezimboni afakwe izinto zokubamba ezithuthukisiwe nezinhlelo zokubona ahamba phambili ekuphatheni amashidi ensimbi amakhulu, amashubhu, kanye nezingxenye ezakhelwe ngaphambili. Ngokwesibonelo:

- Ukukhwabanisa kweshidi lensimbi: Amarobhothi asikwe ngaphambili futhi alolonge amashidi ensimbi noma e-aluminium abe ojantshi befreyimu, ama-crossmembers, kanye nabakaki abanokunemba kwe-sub-millimeter.

- Ukuphatha impahla eyinhlanganisela: Amarobhothi asebenzisanayo (ama-cobots) aphatha ngokuphephile izinto ezingasindi kodwa ezintekenteke njenge-carbon fiber, ehlisa udoti kanye namaphutha omuntu.

2.2 Ubuchwepheshe bokushisela kanye nokuJoyina

I-Welding isalokhu iyisiteji esidinga kakhulu amarobhothi ekukhiqizeni uhlaka. Izinhlelo zesimanje zokushisela amarobhothi ziletha ukuvumelana okungenakuqhathaniswa ezinkulungwaneni zamaphoyinti e-weld:

- I-Resistance spot welding: Amarobhothi anama-axis amaningi enza ukushisela indawo enesivinini esikhulu kumafreyimu ensimbi, aqinisekisa amandla ahlangene afanayo.

- I-laser welding: Amarobhothi anembile afakwe amakhanda e-laser adala ukujoyina okungenamthungo kozimele be-aluminium, ehlisa ukuhlanekezela okushisayo.

- Isicelo sokunamathela: Amarobhothi asebenzisa izinto ezinamathelayo zesakhiwo kumaphethini ayinkimbinkimbi ukuze abophe amafreyimu ayingxube yensimbi eyingxube, inqubo cishe engenakwenzeka ukuyiphindaphinda mathupha.

Indaba eyisibonelo: Umenzi wezimoto ohamba phambili waseYurophu wehlise ukukhubazeka kokushisela ngo-72% ngemva kokukhipha uxhaxha lwamarobhothi e-axis angu-6 anokulungiswa kwendlela eguquguqukayo, ekwazi ukulungisa amapharamitha e-weld ngesikhathi sangempela ngokusekelwe kumpendulo yenzwa.

2.3 Umhlangano kanye Nokudidiyela

Ukuhlanganiswa kozimele kuhlanganisa ukuhlanganisa okokukhweza okumisiwe, abakaki benjini, nezingxenye zokuphepha. Amarobhothi anezingalo ezimbili alingisa ubuhlakani bomuntu ukuze abophe amabhawodi, afake ama-bushings, futhi aqondanise ama-subassemblies. Amasistimu aqondiswa umbono aqinisekisa ukuthi izingxenye zibekwe ngaphakathi kokubekezelelana okungu-±0.1 mm, okubalulekile ekugcineni ukuqondanisa kwe-drivetrain.

2.4 Ukuqinisekisa Ikhwalithi kanye ne-Metrology

Ukuhlolwa kwangemva kokukhiqizwa kubalulekile ukuze kuthotshelwe izimiso zokuphepha. Amasistimu wamarobhothi manje ayasebenza:

- Ukuskena kwe-laser ye-3D: Amarobhothi enza imephu yawo wonke amajiyometri wozimele ukuze athole ukunemba kwe-warping noma ubukhulu.

- Ukuhlolwa kwe-ultrasonic: Ama-automated probe ahlola ubuqotho be-weld ngaphandle kokulimaza izindawo.

- Ukutholwa kokukhubazeka okuxhaswe yi-AI: Ama-algorithms okufunda ngomshini ahlaziya okuphakelayo kwekhamera ukuze kuhlonzwe imifantu emincane noma ukungqubuzana kwenamathela.

Isigaba sesi-3: Izinzuzo Zokuzenzakalela Kwerobhothi Ekukhiqizeni Uhlaka

3.1 Ukunemba kanye Nokuphindaphinda

Amarobhothi ezimboni aqeda ukuhlukahluka kwabantu. Iseli elilodwa lokushisela irobhothi lingagcina ukuphindaphinda okungu-0.02 mm kuyo yonke imijikelezo yokukhiqiza engu-24/7, iqinisekisa ukuthi uhlaka ngalunye luhlangabezana nokucaciswa kwedizayini ncamashi.

3.2 Ukuphepha Kwabasebenzi Okuthuthukisiwe

Ngokuzenzakalela imisebenzi eyingozi efana nokushisela phezulu noma ukuphakamisa izinto ezisindayo, abakhiqizi babike ukwehla okungama-60% kokulimala emsebenzini okuhlobene nokwakhiwa kohlaka.

3.3 Ukusebenza Kahle Kwezindleko

Nakuba ukutshalwa kwezimali kokuqala kubalulekile, amarobhothi anciphisa izindleko zesikhathi eside ngokusebenzisa:

- 30–50% izikhathi zomjikelezo osheshayo

- 20% imfucuza yezinto ezibonakalayo ephansi

- Ukwehliswa okungama-40% kwezindleko zokuphinda kwenziwe kabusha

3.4 Ukunwebeka nokuvumelana nezimo

Amaseli e-robotic ajwayelekile avumela abakhiqizi ukuthi balungise kabusha imigqa yokukhiqiza yemiklamo emisha yozimele. Isibonelo, amafreyimu emoto kagesi (EV) anezivalo zebhethri angahlanganiswa kumasistimu akhona anesikhathi esincane sokuphumula.

Isigaba 4: Ukunqoba Izinselele Ekwenziweni Kohlaka LweRobhothi

4.1 Izinkinga Zokuhambisana Kwempahla

Ukushintshela kumafreyimu wezinto eziningi (isb, ama-steel-aluminium hybrids) kudinga amarobhothi ukuthi aphathe izindlela zokujoyina ezingafani. Izixazululo zifaka:

- Amakhanda okushisela amaHybrid ahlanganisa ubuchwepheshe be-arc ne-laser

- Izibambi zikaZibuthe zokuphatha izinsimbi ezingenayo ayoni

4.2 Ubunkimbinkimbi bezinhlelo

Isoftware ye-Offline irobhothi (OLP) manje ivumela onjiniyela ukuthi balingise futhi bathuthukise ukugeleza komsebenzi wamarobhothi ngedijithali, banciphise isikhathi sokusebenza ngokufika ku-80%.

4.3 Izingozi Ze-Cybersecurity

Njengoba ukukhiqizwa kohlaka kuya ngokuya kuxhumeka nge-Industrial IoT, abakhiqizi kumele basebenzise izivumelwano zokuxhumana ezibethelwe kanye nezibuyekezo ezijwayelekile ze-firmware ukuvikela amanethiwekhi amarobhothi.

Isigaba 5: Ikusasa Lokukhiqiza Uhlaka LweRobhothi

5.1 Ukukhiqiza Okuguquguqukayo Okuqhutshwa yi-AI

Amarobhothi esizukulwane esilandelayo azosebenzisa ubuhlakani bokwenziwa ukuze:

- Amathuluzi wokuzilinganisa ngokusekelwe ekugqileni kwezinto

- Qagela futhi unxephezele ngokuguga kwamathuluzi

- Lungiselela ukusetshenziswa kwamandla ngesikhathi sokufunwa okuphezulu

5.2 Ukusebenzisana Kwerobhothi Lomuntu

Ama-Cobots anamajoyinti alinganiselwe azosebenza kanye nochwepheshe ukuze kulungiswe uhlaka kokugcina, kuhlanganiswe ukwenza izinqumo komuntu nokunemba kwerobhothi.

5.3 Ukukhiqiza Okuzinzile

Amasistimu wamarobhothi azodlala indima ebalulekile ekuzuzeni ukukhiqizwa okuyindilinga:

- Ukuqaqa okuzenzakalelayo kozimele bokuphela kwempilo ukuze bagaywe kabusha

- Ukunemba kokubekwa kwempahla ukuze kuncishiswe ukusetshenziswa kwempahla eluhlaza

Isiphetho

Ukuhlanganiswa kwamarobhothi ezimboni ekukhiqizweni kohlaka lwezimoto kumelela okungaphezu nje kwentuthuko yezobuchwepheshe—kusho ushintsho olubalulekile endleleni izimoto ezicatshangelwa futhi zakhiwe ngayo. Ngokuletha ukunemba okungenakuqhathaniswa, ukusebenza kahle, nokuvumelana nezimo, amasistimu wamarobhothi anika abakhiqizi amandla okuhlangabezana nezidingo eziguqukayo zezimoto eziphephile, ezilula, nezizinzile. Njengoba i-AI, izinzwa ezithuthukisiwe, kanye nobuchwepheshe obuluhlaza buqhubeka nokuvuthwa, ukusebenzisana phakathi kwamarobhothi nobunjiniyela bezimoto ngokungangabazeki kuzoqhubezela imboni emazingeni angakaze abonwe ezinto ezintsha.

Ezinkampanini ezisebenza ngokukhethekile ngamarobhothi ezimboni, lolu shintsho lunikeza amathuba amakhulu okusebenzelana nabakhiqizi bezimoto ekuchazeni kabusha ikusasa lokuhamba—uhlaka olulodwa olwakhiwe kahle ngesikhathi.

Ukubala Kwamagama: 1,480

Imigomo Ebalulekile: Amarobhothi ohlaka lwezimoto, amasistimu wokushisela amarobhothi, i-AI kwezokukhiqiza, amarobhothi asebenzisanayo, ukukhiqizwa okusimeme

Izincomo ze-SEO: Faka phakathi izincazelo ze-meta eziqondise "i-automotive frame automation" kanye "namarobhothi wezimboni we-chassis yemoto." Sebenzisa izixhumanisi zangaphakathi ezifundweni ezihlobene noma amakhasi omkhiqizo.

Isikhathi sokuthumela: Mar-26-2025