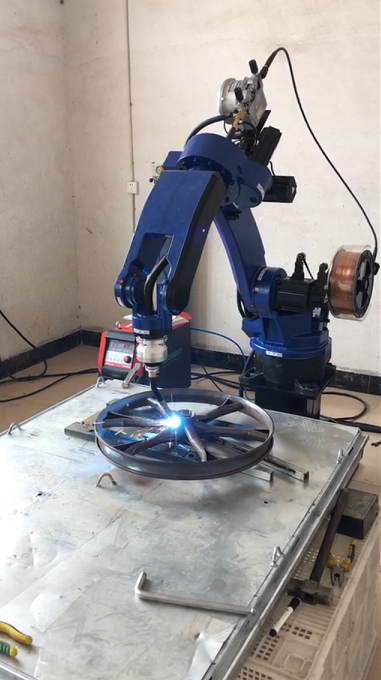

Kunezizathu eziningi zokuthi kungani i-robot yokushisela ishisa ithiphu yokuxhumana phakathi nenqubo yokukhiqiza i-welding. Isibonelo, isenzakalo esingaphezulu sokushintshwa njalo kwethiphu yokuxhumana yilo: ukuguga kwe-outlet yethiphu yokuxhumana kubangela ukuphakela kwentambo ukuthi kuphambuke, futhi ithrekhi yokushisela yangempela iyagudluzwa, okungukuthi, ukushintshwa kwendawo yephoyinti le-TCP, Okuholela ekushiyekeni kokushisela okufana ne-welding offset noma ukuvuza kokushisela.

Ukuhlaziywa Kwezinkinga Ezibangelwa Ukushiswa Kwerobhothi Le-Welding Ithiphu Yokuxhumana

1. Isizathu sokwehluleka kwethiphu yokuxhumana uqobo

Ukugqokwa kwephuzu lokuxhumana lerobhothi elishisela ngokwalo kubangelwa ukuguga lapho kuphuma ithiphu yokuxhumana ngenxa yokungqubuzana kokuphakelayo kwezintambo okuqhubekayo ngaphansi kwezinga lokushisa elikhuphukayo lethiphu yokuxhumana. Ngesikhathi sokusebenza kwe-welding yerobhothi yokushisela, amaphutha okulinganisa avame ukwenzeka futhi athinte ukukhiqizwa. ukusebenza kahle. Ngalesi sikhathi, kufanele uzame ukunciphisa izinga lokushisa lethiphu yokuxhumana, okuhlanganisa ukubunjwa kwephuzu lokuxhumana kanye nokucubungula kwesakhiwo sethiphu yokuxhumana. Impahla yethiphu yokuxhumana: ithusi, ithusi elibomvu, phakathi kwayo i-chromium zirconium yethusi iyona engcono kakhulu; ngisho nokwengeza izingxenye ze-ceramic kuthiphu yokuxhumana kungakhuphula ukumelana nokugqoka. Okwesithathu ukunemba kokucubungula kwethiphu yokuxhumana. Ngenxa yokunemba kwemishini yokucubungula noma ezinye izinkinga, ukuqedwa kwembobo yangaphakathi kanye nokugxila kwethiphu yokuxhumana akulungile ngokwanele.

2. I-arc ayizinzile, okwenza i-arc ibuye ivutha

Esinye sezimbangela sihlanganisa ukuntula okuncane kwe-arc, i-arc engazinzile, ukuphakelwa kwezintambo okungalungile, ukuhlanzeka kwendawo yokusebenza, njll., kodwa akuthinti ukusebenza kwethiphu yokuxhumana ngokwayo. Ngalesi sikhathi, ukwehluleka kokushisela kuhlobene cishe nezici zomthombo wamandla wokushisela kanye nekhwalithi yocingo lokushisela. , umthelela wokuphakela ngocingo, ipayipi lokuphakela izintambo kanye nomklamo wesakhiwo sokuxhumana nozzle. Lapho i-welding wire kanye nephuzu eliqhutshwayo kuphuzu lokuxhumana lishintsha njalo, impilo yalo iyingxenye kuphela lapho iphuzu lokuqhuba lizinzile.

3. Izizathu zokuqondisa izintambo nokuqedwa kwendawo

Intambo yokushisela yerobhothi yokushisela ivamise ukupakishwa emgqonyeni noma epuletini, futhi inama-burrs noma izimbambo, ngakho-ke ingase ithinte ukuxhumana phakathi kwentambo yokushisela kanye nethiphu yokuxhumana. Lapho irobhothi elishiselayo lishisela, ithiphu yokuxhumana kufanele iqhube kahle ngaphansi kwesisekelo Inikeza ukungqubuzana okuncane. Impilo yethiphu yokuxhumana yentambo yokushisela engcolile ingaba ingxenye eyodwa kwezintathu kuphela yokusebenzisa intambo yokushisela ehlanzekile; ukwahlulela ikhwalithi yocingo lokushisela, izinga lokukhululeka kwengcindezi yocingo lokushisela, ukusebenza kuwukuthi ubuqotho bunjani: impendulo yokuhlola ingu-50mm ukusuka ngaphambili kwesibhamu sokushisela i-acrobatic, noma intambo yokushisela ingaba Ukugoqa ngokuzenzakalelayo, ukugobela phambili kusho ukuthi ucingo lokushisela luthambile kakhulu, ukugoba ngemuva kusho ukuthi luqine kakhulu, ucingo oluqinile lubiza kakhulu; okwesibili, ukuthi ipayipi lokuphakela ngocingo elisuka ku-wire feeder kuya kusibhamu sokushisela ligobile lizokwenza ukuthi intambo yokushisela igotshwe. i-camber.

Isikhathi sokuthumela: Apr-24-2022