Isingeniso

Umkhakha wokukhiqiza izimoto uya ngokuya uncika kumarobhothi ezimboni ukuze uzuze ukunemba, ukusebenza kahle, nokungaguquguquki ekukhiqizeni. Phakathi kwezicelo ezibaluleke kakhulu ukushiselwa kwezingxenye zezimoto, ikakhulukaziama-ekseli(obeye aziwe njengoama-ekseli emotonomaama-ekseli emoto), okubalulekile ekuzinzeni kwemoto, ukudluliswa kwamandla, nokuthwala umthwalo. Lesi sihloko sihlola ukuthi kuthuthuke kangakananiama-robotic welding systemsbenza izinguquko ekukhiqizeni ama-ekseli nezinye izingxenye zezimoto, kuyilapho begqamisa amagama angukhiye aphezulu kukho kokubiliizingxenye zezimotofuthiamarobhothi welding.

Isigaba 1: Izingxenye Ezibalulekile Zezimoto Ekugxileni

Ukukhiqizwa kwezimoto kubandakanya ukuhlanganisa okuyinkimbinkimbi, okunezingxenye ezilandelayo ezibalulekile ekusebenzeni kwemoto. Naziamagama angukhiye engxenye yezimoto angu-5 aphezuluokuhambisana nale ngxoxo:

- I-Axle (I-Axle yemoto/i-Axle yemoto)

Ama-ekseli amaphakathi ne-drivetrain yemoto, amasondo axhumayo futhi asekela isisindo semoto. I-Precision welding iqinisekisa ubuqotho besakhiwo nokuqina. - Amasistimu Wokumisa

Izingxenye ezifana nezingalo zokulawula nama-struts zidinga ukushiselwa okuqinile ukuze zimelane nengcindezi yomgwaqo. - Izingxenye ze-Drivetrain

Izingxenye ezifana nezindlu ezihlukene kanye nezinsimbi zokudlulisela zithembele kumashisela anamandla aphezulu. - Amafreyimu e-Chassis

Umgogodla wemoto, amafreyimu e-chassis adinga ikhwalithi yokushisela engaguquki ukuze kuphephe. - I-Exhaust Systems

Ukushisela okuyinkimbinkimbi kuma-nifolds namapayipi kufanele amelane nokushisa nokugqwala.

Kulokhu,i-axle weldingigqama ngenxa yobunkimbinkimbi bayo bezobuchwepheshe kanye nomthelela ekusebenzeni kwemoto.

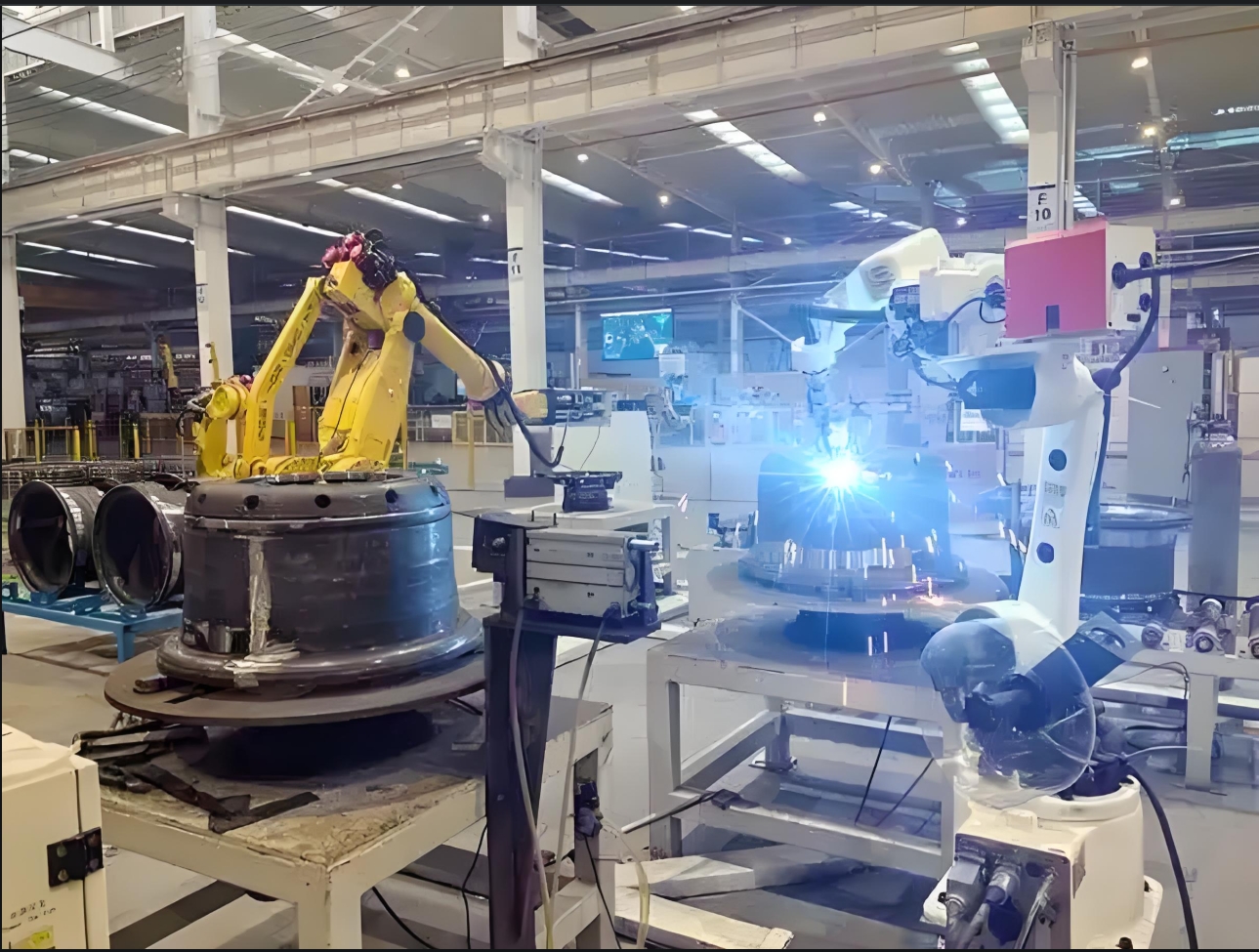

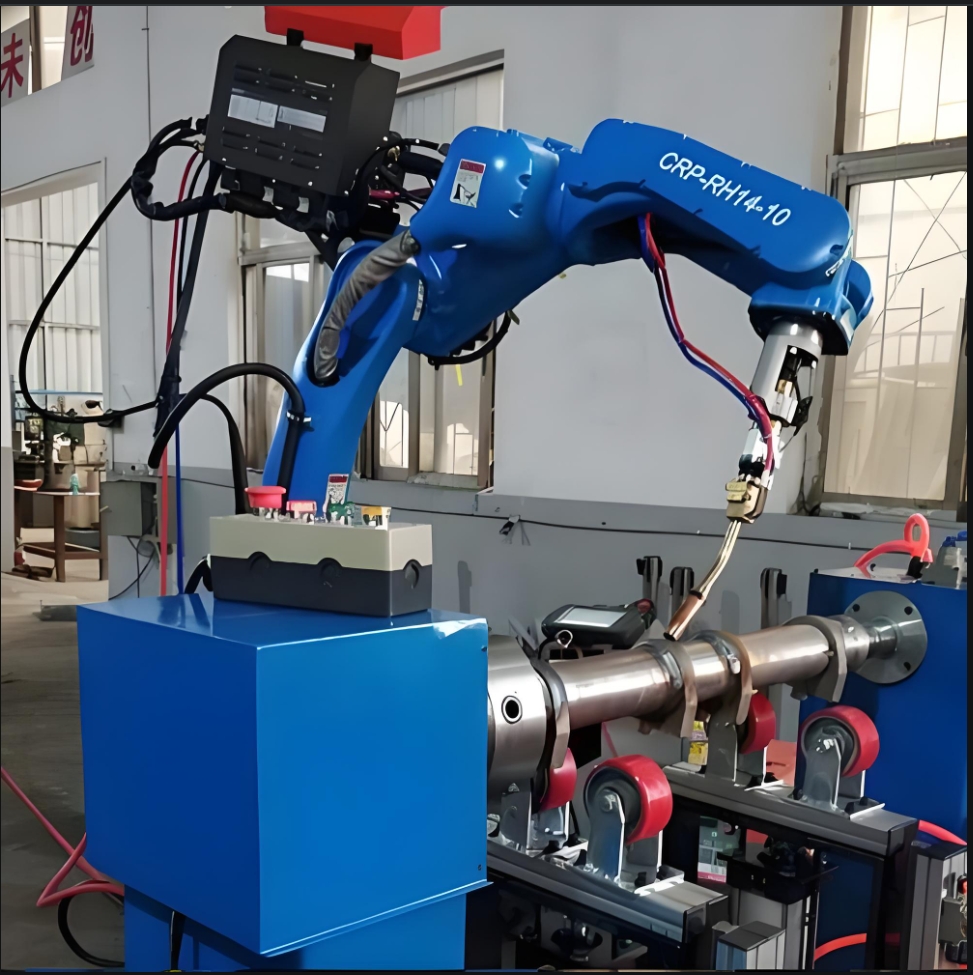

Isigaba 2: Amarobhothi Welding Yezimboni: Ubuchwepheshe Namakhono

Okwesimanjeama-robotic welding systemshlanganisa ubuchwepheshe obuthuthukisiwe ukuze uhlangabezane nezindinganiso zezimoto. Ngezansi kukhonatop 5 welding irobhothi angukhiye:

- Ukushisela okuzenzakalelayo

I-Automation iqinisekisa ukuphindaphinda futhi inciphisa iphutha lomuntu ekukhiqizeni ivolumu ephezulu. - I-Arc Welding (MIG/TIG)

Kuncanyelwa ukwenziwa kwe-ekseli ngenxa yokungena okujulile nokwakheka kwamalunga aqinile. - I-Laser Welding

Isetshenziselwa imisebenzi enembayo ephezulu, njengokushisela ama-axle shafts amancane anokuhlanekezela okuncane. - Spot Welding

Ilungele ukuhlanganisa amashidi ensimbi agqagqene ezingxenyeni ezimisiwe noma ze-chassis. - Amarobhothi Asebenzisanayo (Ama-Cobots)

Thuthukisa ukuguquguquka ezindaweni zokukhiqiza okuxubile, usebenzisana nochwepheshe.

Lobu buchwepheshe buvumela abakhiqizi ukuthi bazuzeI-zero-defect weldingezingxenyeni ezibalulekile njengama-ekseli.

Isigaba sesi-3: Ama-Axles Welding Anamarobhothi Wezimboni: Inqubo kanye Nezinzuzo

Isinyathelo 1: Idizayini nokuhlela

Ukushisela i-axle kuqala ngokulingiswa kwe-CAD/CAM ukuze kuthuthukiswe izindlela zokushisela. Amarobhothi ahlelelwe ukunyakaza kwama-axis amaningi, aqinisekisa ukufinyelela kumajometri ayinkimbinkimbi.

Isinyathelo sesi-2: Ukulungiselela Okubalulekile

Ama-ekseli ngokuvamile enziwa ngensimbi yokuqina okuphezulu noma ama-alloys e-aluminium. Amasistimu erobhothi ahlanzeke ngaphambilini izindawo kanye nezingxenye zokubopha ukuze kuncishiswe ukungahambi kahle.

Isinyathelo sesi-3: Ukubulawa Kwe-Welding

- I-Arc Welding: Isetshenziselwa i-axle housings ewugqinsi, iqinisekisa ukujula, imithungo efanayo.

- I-Laser Welding: Kusetshenziswa kumalunga anemba kumadizayini we-asindi ye-asindi.

- Izinzwa zokulandelela i-Seam: Nxephezela ukungahambisani kwezinto ngesikhathi sangempela.

Izinzuzo ze-Robotic Axle Welding:

- Amandla Athuthukisiwe: Ama-welds angaguquki anciphisa amaphuzu abuthakathaka.

- Izikhathi Zomjikelezo Osheshayo: Amarobhothi asebenza 24/7, akhuphula ukuphuma.

- Ukonga Izindleko: Amazinga aphansi e-scrap kanye nezindleko ezincishisiwe zabasebenzi.

- Ukuphepha: Iqeda ukuchayeka ezinhlansini kanye nentuthu kubasebenzi.

Isigaba 4: Amathrendi Embonini Abumba Ukushisela Kwerobhothi

- I-AI-Powered Quality Control

Ama-algorithms okufunda komshini ahlaziya ubuqotho be-weld, ukuhlaba umkhosi amaphutha ngesikhathi sangempela. - Lightweighting Izidingo

Amarobhothi ajwayela ukushisela izinto ezithuthukile njengezinhlanganisela ze-aluminium-carbon yama-ekseli emoto kagesi (EV). - Ukuhlanganiswa kwe-IoT

Amarobhothi ahlakaniphile adlulisela idatha yokusebenza kumasistimu amaphakathi ukuze alungiswe kusengaphambili. - Ukusimama

Izinqubo zokushisela ezonga amandla zinciphisa imikhondo ye-carbon.

Lawa mathrendi amiama-robotic welding systemsnjengento ebaluleke kakhulu ezimbonini zesimanje zezimoto.

Isigaba 5: Izinselelo Nezixazululo

Ngenkathi ukushiswa kwe-robotic kunikeza izinzuzo ezinkulu, izinselelo ziyaqhubeka:

- Utshalomali Olukhulu Lokuqala: Kuncishiswe yi-ROI yesikhathi eside kusukela ekukhuleni kokukhiqiza.

- I-Complex Programming: Kwenziwe lula ngezisetshenziswa ezisebenziseka kalula namathuluzi okulingisa angaxhunyiwe ku-inthanethi.

- Ukuhlukahluka Kwempahla: Kubhekwane nezinzwa eziguquguqukayo kanye nokulungiswa okuqhutshwa yi-AI.

Okokushisela i-axle, ukusebenzisana nabanolwaziabakhiqizi bezimboni zamarobhothiiqinisekisa izixazululo ezenzelwe wena.

Isiphetho

Ukushiselwa kwezingxenye zezimoto njengama-ekseli kuyisibonelo samandla okuguqulaamarobhothi ezimboni. Ngokusebenzisa amandlai-welding ezenzakalelayo,i-arc welding, futhilaser weldingubuchwepheshe, abakhiqizi bafinyelela ukunemba okungenakuqhathaniswa nokusebenza kahle. Njengoba imboni yezimoto ithuthuka—ikakhulukazi ngokukhula kwama-EV—ama-robotic welding systemsizohlala ibalulekile ekukhiqizeni izingxenye ezihlala isikhathi eside, ezisebenza kahle kakhulu. Kumabhizinisi afuna ukwenza imigqa yawo yokukhiqiza ibe yesimanje, ukutshala imali kumarobhothi okushisela akuwona nje inketho kodwa kuyisidingo.

Amagama angukhiye: I-Axle, I-Axle Yemoto, Amasistimu Okumiswa, Izingxenye Ze-Drivetrain, Amafreyimu e-Chassis; I-Automated Welding, i-Robotic Welding Systems, i-Arc Welding, i-Laser Welding, i-Spot Welding.

Isikhathi sokuthumela: Apr-02-2025