Imboni yezimoto ifana nokuqamba izinto ezintsha, efuna ukunemba okungaphezi, isivinini, nokwethembeka ekukhiqizweni kwengxenye. Phakathi kwezingxenye zezimoto ezibalulekile, amasistimu wokukhipha umoya—ikakhulukazi amapayipi okukhipha umoya—adlala indima ebalulekile ekusebenzeni kwemoto, ekulawuleni ukungcola, nasekunciphiseni umsindo. Njengoba abakhiqizi belwela ukuhlangabezana nezindinganiso eziqinile zekhwalithi kanye nemigomo yokukhiqiza, amarobhothi okushisela avele njengamathuluzi abalulekile ekwenzeni amasistimu e-exhaust. Lesi sihloko sihlola ukuthi izinhlelo ze-robotic welding, ezihlanganiswe nemishini yokumisa ethuthukisiwe njengeama-rotary tilt positionersfuthiizinto ezenziwe ngokwezifiso, benza izinguquko ekukhiqizeni amapayipi kagesi wezimoto, bakhuphule ukusebenza kahle, ukungaguquguquki, kanye nekhwalithi yomkhiqizo ibe sezingeni elingakaze libonwe ngaphambili.

1. Ubunzima Bokwenziwa Kwepayipi Le-Exhaust

Amapayipi e-exhaust angaphansi kwezimo ezimbi kakhulu, okuhlanganisa izinga lokushisa eliphezulu, amagesi abolayo, nokudlidliza kwemishini. Ukuze umelane nalezi zinselele, ngokuvamile zenziwa ngensimbi engagqwali noma insimbi e-aluminium futhi zidinga amashisela angenamthungo, angangeni moya kuwo wonke amajiyometri ayinkimbinkimbi. Izinqubo zokushisela okwenziwa ngesandla ngokuvamile zithwala kanzima ukuze kugcinwe ukuvumelana ezinhlelweni ezinjalo, okuholela ekulimaleni okufana ne-porosity, ukuhlanganisa okungaphelele, noma ukuhlanekezela.

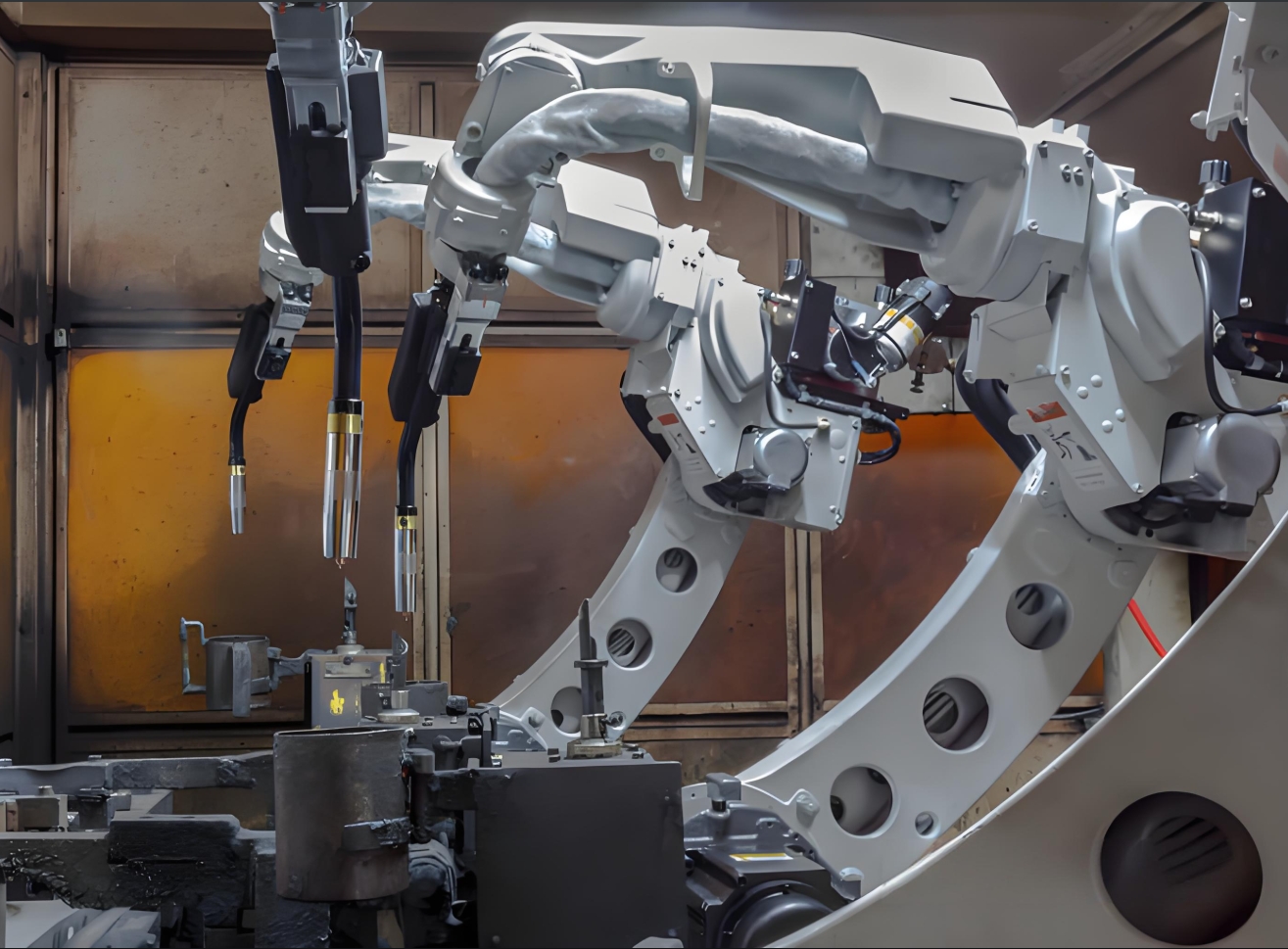

Amarobhothi okushisela, nokho, ahamba phambili ekuphatheni lezi zinkimbinkimbi. Ifakwe i-multi-axis yokuphimisa futhi ivunyelaniswe nezinhlelo zokubeka indawo enembayo, ziletha ama-weld angenasici ezindaweni ezigobile, ama-flange, namajoyinti—okubalulekile ekuqinisekiseni ubuqotho besistimu yokukhipha umoya.

2. I-Robotic Welding in Action: Izicelo Eziyinhloko Zokukhipha Amapayipi

2.1 I-Tube-to-Flange kanye ne-Tube-to-Muffler Welding

Amasistimu e-exhaust ahlanganisa izingxenye eziningi, okuhlanganisa amapayipi, iziguquli ze-catalytic, ama-resonator, nama-muffler. Amasistimu wokushisela amarobhothi enza ngokuzenzakalelayo ukuhlangana kwamashubhu kuya kuma-flange noma ama-muffler housings, aqinisekise ukungena okufanayo kanye nokunciphisa izindawo ezithinteke ekushiseni (HAZ). Ngokwesibonelo, a6-eksisi irobhothi elicacisiweingakwazi ukuzungeza isiyingi sepayipi, igcine ama-engeli ethoshi afanele kanye nesivinini sokuhamba ngisho nasezindaweni ezikhonkolo.

2.2 I-Laser Welding Yezingxenye Ezinezindonga Ezincane

Amapayipi okukhipha umoya wesimanje ngokuvamile afaka imiklamo enezindonga ezincane ukuze unciphise isisindo ngenkathi ugcina amandla. Amarobhothi we-laser welding, anomthamo wawo omkhulu wamandla kanye ne-weld seam emincane, avimbela ukungqubuzana futhi alondoloze izakhiwo zezinto ezibonakalayo. Lokhu kunenzuzo ikakhulukazi kumasistimu wokukhipha insimbi engagqwali, lapho ukunemba kubaluleke kakhulu.

2.3 I-Multi-Pass Welding Yamajoyinti Aminyene

Kuzinhlelo zokukhipha umoya osindayo ezimotweni zentengiso, amasistimu e-robotic gas metal arc welding (GMAW) asebenzisa ama-multi-pass weld ukuze akhe amalunga aqinile phakathi kwamapayipi anezindonga eziwugqinsi nabakaki. I-Adaptive welding algorithms ilungisa imingcele ngesikhathi sangempela ukuze ivumelane nokuhlukahluka kwezinto.

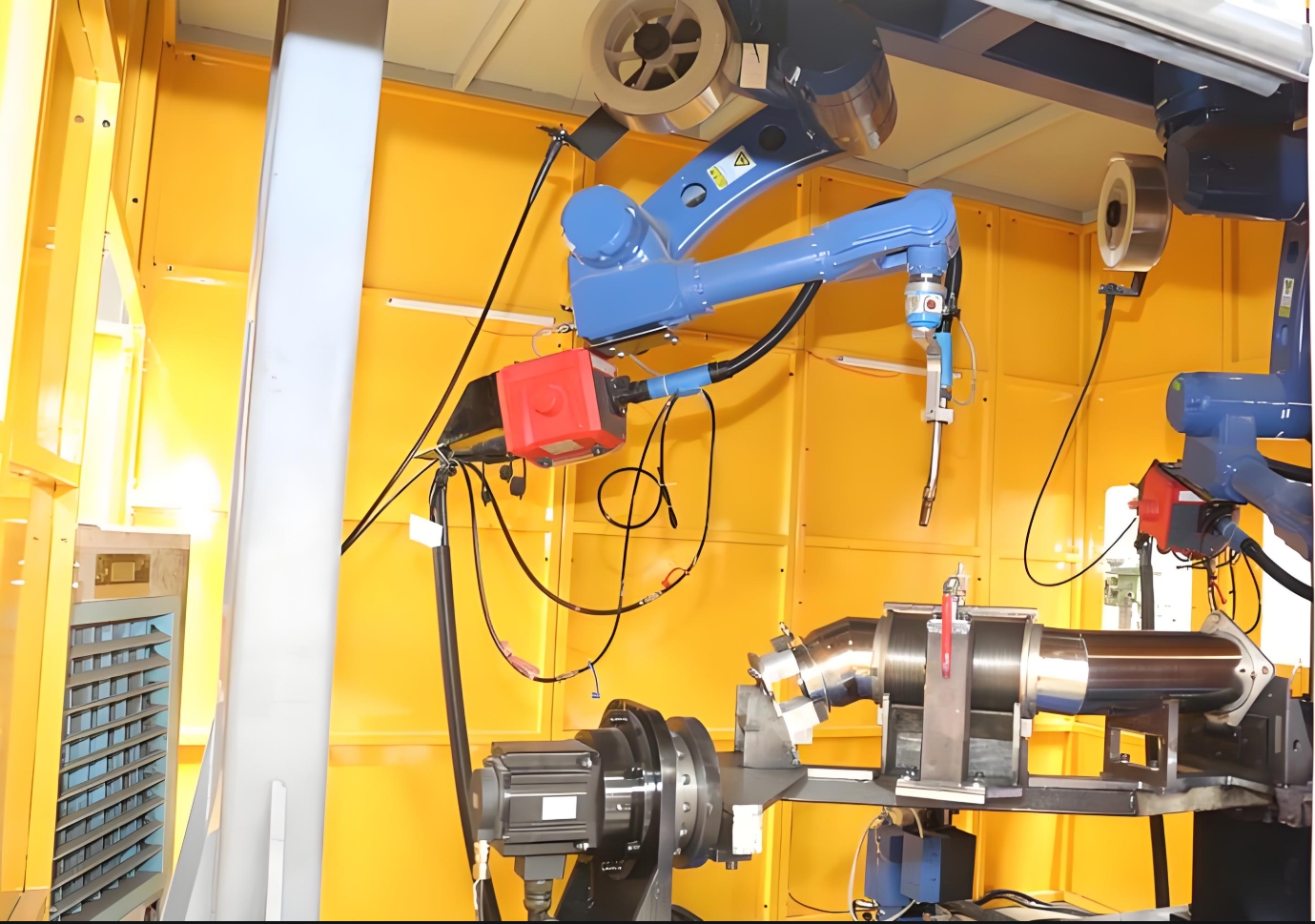

3. Ukuthuthukisa Ukuguquguquka Nge-Rotary Tilt Positioners

Ukusebenza kahle kweseli yokushisela i-robotic kuncike ekusebenzisaneni okungenazihibe phakathi kwerobhothi nomsebenzi.Ama-rotary tilt positionerszibalulekile kule nqubo, zivumela ukuzungezisa okungu-360-degree kanye nokutshekiswa kwamapayipi okukhipha umoya ngesikhathi sokushisela. Izinzuzo zihlanganisa:

- Ukufinyelela Okuhlangene Okulungile: I-positioner iqondisa kabusha ipayipi ukuze yethule i-weld seam endaweni eyisicaba noma evundlile, yenza uhlelo lwamarobhothi lube lula kanye nokunciphisa izikhathi zokujikeleza.

- Ukubeka Kabusha Okuncishisiwe: Ngokulungisa i-workpiece enamandla, irobhothi lingaqedela ukushisela okuningi ngokusetha okukodwa, ukunciphisa isikhathi sokungenzi lutho.

- I-Ergonomics ethuthukisiwe: Ama-opharetha alayisha/akhipha izingxenye ngenkathi irobhothi lishisela, okwenza kube ngcono ukuphuma.

Isibonelo, indawo yokubeka iziteshi ezimbili ivumela ipayipi elilodwa ukuthi lishiselwe kuyilapho elilandelayo lilayishwa, lizuza ukukhiqizwa okuqhubekayo okuqhubekayo.

4. Ukulungisa Okunembile: Umgogodla Wokuvumelana

Ngokwezifisoizinto ze-weldingzibalulekile ekubambeni izingxenye ze-exhaust ziqondane ncamashi ngesikhathi sokushisela i-robotic. Ukucatshangelwa kwedizayini okubalulekile kuhlanganisa:

- Izindlela Zokubamba: Izinsimbi zomoya noma ze-hydraulic zivikela amapayipi, ama-flange, nabakaki ngaphandle kokumasha izindawo.

- I-Modularity: Izinto ezilungiswayo ezishintsha ngokushesha zithatha ububanzi obuhlukahlukene bamapayipi noma ukumiswa, okulungele ukukhiqizwa kwemodeli exubile.

- Ukuphatha Okushisayo: Izinto ezilungiswayo ezenziwe ngezinto ezikwazi ukumelana nokushisa zimelana nokuchayeka isikhathi eside kuma-arc welding.

Ukulungiswa okuthuthukisiwe kuhlanganisa izinzwa ukuze kuqinisekiswe ukubekwa kwengxenye ngaphambi kokuthi kuqale ukushisela, kuqede izinkinga zokungaqondani kahle.

5. Ukulinganisa Izinzuzo Zokuphumelela

Ukwamukelwa kwezinhlelo zokushisela amarobhothi ekukhiqizeni amapayipi e-exhaust kuletha intuthuko elinganisekayo:

- Ukunciphisa Isikhathi Somjikelezo: I-robotic MIG welder ingaqedela ukushisela okuzungezile kumasekhondi angu-60, uma kuqhathaniswa namasekhondi angu-180+ wokushisela ngesandla.

- I-Higher Uptime: Amarobhothi asebenza ngo-24/7 anesikhathi esincane sokuphumula, akhuphula ukuphuma konyaka ngo-30–50%.

- Ukonga Okubalulekile: Ukulawulwa kwepharamitha okunembile kunciphisa i-spatter nokusebenza kabusha, kwehlisa izindleko ezisebenzisekayo ngo-15-20%.

Isibonelo, umphakeli wezimoto we-Tier-1 ubike aUkukhuphuka ngo-40% kokusebenzangemva kokukhipha amaseli erobhothi anezindawo ezivumelanisiwe zokuhlanganisa i-exhaust.

6. Ukuphakamisa Ikhwalithi Kumazinga Ezimoto

I-Robotic welding iqinisekisa ukuhambisana namabhentshimakhi ekhwalithi yezimoto njenge-IATF 16949:

- Ukuphindaphinda: Amarobhothi aphindaphinda izindlela zokushisela ngokunemba okungu-±0.1 mm, asusa ukuhlukahluka kwabantu.

- Ukutholwa Kwesici: Amasistimu ombono ahlanganisiwe noma izinzwa zokuqapha i-arc zithola ukungahambi kahle phakathi nenqubo, okubangela ukulungiswa okusheshayo.

- Amadokhumenti: Amasistimu azenzakalelayo akhiqiza izingodo ze-weld ezilandelekayo, ezibalulekile ekucwaningweni kwamabhuku kanye nokukhumbula.

Ukuhlolwa kwe-post-weld kuveza ukuthi amasistimu erobhothi anciphisa i-porosity kanye namazinga okuqhekeka ngaphezulu kwama-90% uma kuqhathaniswa nezindlela ezenziwa ngesandla.

7. Ukusimama kanye Nezitayela Zesikhathi esizayo

Abakhiqizi bezimoto baya ngokuya bebeka phambili ukusimama. I-Robotic welding isekela lolu shintsho ngokuthi:

- Ukunciphisa Ukusetshenziswa Kwamandla: Isikhathi esisebenza kahle se-arc nezindlela zokunyakaza ezithuthukisiwe zehlisa ukusetshenziswa kwamandla.

- Ukunciphisa Imfucuza: Amazinga aphezulu esivuno sokuqala anciphisa izinsalela.

- Inika amandla i-Lightweighting: Ukushisela okunembayo kusiza ukusetshenziswa kwezinto ezithuthukisiwe, ezincanyana ngaphandle kokubeka engcupheni ukuqina.

Ngibheke phambili,Amarobhothi okushisela aqhutshwa yi-AIizosebenzisa ukufundwa komshini ukuze izenzele ngokwakho amapharamitha wezinto ezintsha, kuyilaphoamarobhothi asebenzisanayo (ama-cobots)izosiza abaqhubi ekukhiqizeni amaqoqo amancane.

Isiphetho

Emkhakheni wezinga eliphezulu wokukhiqizwa kwesistimu ye-exhaust yezimoto, amarobhothi ashiselayo—engezwe yizindawo ezihlakaniphile nezilungiswayo—amele isiqongo sobunjiniyela obunembayo. Ngokuzenzakalela imisebenzi yokushisela eyinkimbinkimbi, lezi zinhlelo zinika abakhiqizi amandla okufinyelela izikhathi zokujikeleza ezisheshayo, ikhwalithi enhle, kanye nokukhiqiza okungaka. Njengoba imithetho yokukhipha umoya iqina kanye nemiklamo yezimoto ithuthuka, ubuchwepheshe bokushisela i-robotic buzohlala buyisisekelo sokusungula izinto ezintsha, buqhubekisela phambili imboni yezimoto ibheke ekusaseni elihlakaniphile nelihlanzekile.

Kubakhiqizi bamarobhothi ezimbonini, ukugcizelela la makhono ekusetshenzisweni kwamapayipi e-exhaust akugcini nje ngokugqamisa ubuchwepheshe kodwa futhi kubeka izixazululo zabo njengabalingani ababalulekile ekuthuthukiseni ubuhle bokukhiqiza izimoto.

Isikhathi sokuthumela: Mar-21-2025