Ukushisela i-Robotic Mig -----Isixazululo sokushisela i-Street Lamp Pole

Inkomba

1. Ulwazi lwesiqephu somsebenzi

2. Robotic Welding Solution Uhlolojikelele

3. Robotic Welding Solution Process

4. Ukucushwa Kwezisetshenziswa zeRobhothi

5. Umsebenzi Omkhulu 6. Ukwethulwa Kwezisetshenziswa

7. Ukufakwa, Ukugunyazwa kanye Nokuqeqeshwa

8. Hlola kanye Nokwemukelwa

9. Izidingo Zemvelo

10. Iwaranti kanye nesevisi yangemuva kokudayiswa

11. Ukulethwa Kwemibhalo Enamathiselwe

Ividiyo yesicelo sokushisela i-Robotic

1, Ulwazi Lomsebenzi

-Welding wire DiameterUsayizi: Ф1.2mm

-Inqubo yokushisela: ukushisela okuvikelwe ngegesi/ukushisela i-Mig

-Uhlobo lomthungo we-Weld: uhlobo lomugqa oqondile, uhlobo lombuthano

-Ukuvikela igesi:99% CO2

-Indlela Yokusebenza: ukulayisha nokukhipha ngesandla, ukushisela okuzenzakalelayo kwerobhothi

-Iphutha Lokufaka:≤ 0.5mm

-Ukuhlanza Plate :i-metallic luster ingabonakala ku-weld kanyengaphakathi kwebanga lokuphakama okuphindwe kabili kwe-weld seam nhlangothi zombili

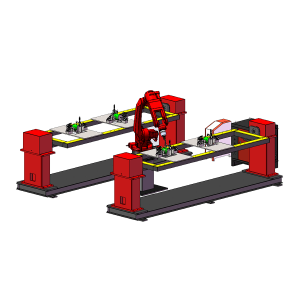

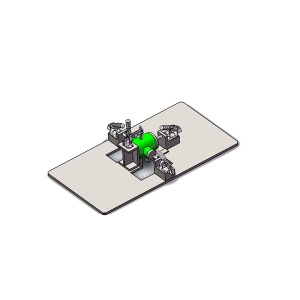

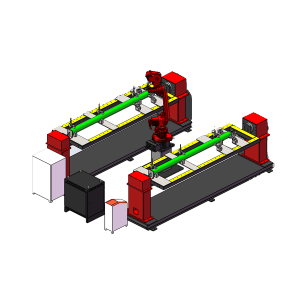

2, Robotic welding solution Uhlolojikelele

Ukuze kuthuthukiswe ukusebenza kahle komsebenzi, ngokusho kwesimo sangempela se-workpiece, imboni ye-Honyen izohlinzeka ngesethi yendawo yokusebenza yerobhothi yokushisela, engathathelwa indawo ngamathuluzi ahlukene ukuze ahambisane nemikhiqizo ehlukene.Indawo yokusebenzela yakhiwe ngemodeli yamarobhothi: irobhothi lokushisela i-HY1006A-145, umthombo wamandla wokushisela, ithoshi yokushisela ekhethekile yerobhothi, iKhabhinethi yokulawula ugesi nezinkinobho, isibandisi sokupholisa amanzi, izifanisi zesiteshi esisebenza kabili, izinto ezisetshenziswayo, ucingo lokuvikela ukuphepha (uyazikhethela) nokunye. izingxenye.

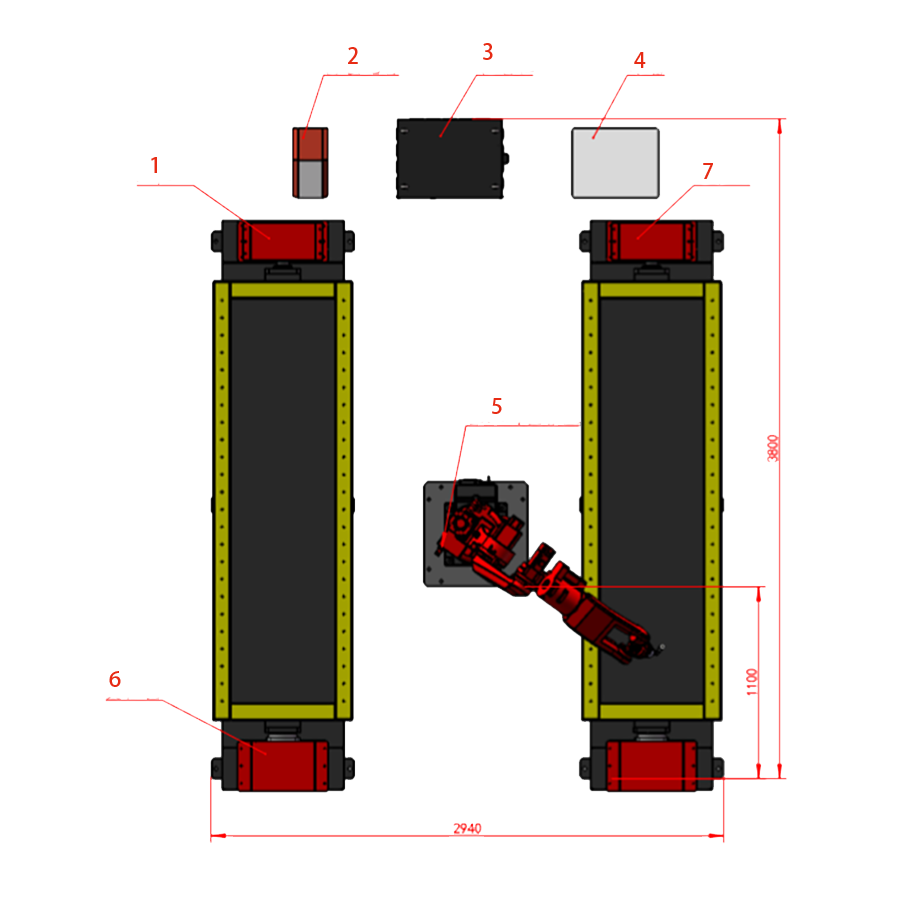

3, Isethulo se-Mig Welding irobhothi yokusebenzela Isakhiwo

I-Honyen irobhothi arc welding workstation Isakhiwo

1, Isiteshi sokusebenza 1

2, Welding Power umthombo

3, Isilawuli serobhothi

4, I-chiller yokupholisa amanzi

5, Honyen arc welding Robot, HY1006A-145

6, Isikhundla

7, Isiteshi sokusebenza 2

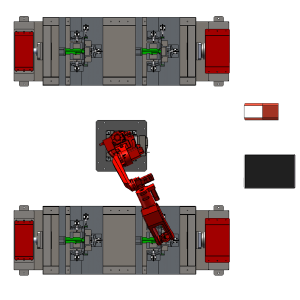

Izingxenye zezigxobo zikagesi

Izingxenye zezigxobo zikagesi 2

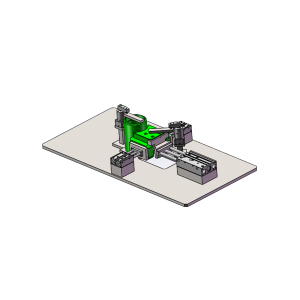

Izixazululo ze-Robotic welding Isakhiwo 1

Ukulungiswa Kwezingxenye Zesigxobo Kagesi 3

Izixazululo ze-Robotic welding Isakhiwo 2

Izixazululo ze-Robotic welding Isakhiwo sesi-3

4. Robotic Welding Solution Process I. I-Operator ilayisha umsebenzi esiteshini 1, Ngemva kokuyilayisha nokuyicindezela.U-opharetha ucindezela inkinobho yokuqala yokubhuka irobhothi 1, futhi irobhothi liqala ukushisela okuzenzakalelayo;

II.I-opharetha iya esiteshini 2 ukuze ilayishe izingcezu zokusebenza.Ngemva kokulayisha i-workpiece, i-Operator icindezela inkinobho yokuqala yokubhukha yerobhothi 2 bese ilinda irobhothi liqeda ukushisela;

III.Ngemva kokuba irobhothi seliqede ukushisela esiteshini 1, lizenzela ngokuzenzakalelayo uhlelo lwesiteshi sesi-2;

Ⅳ.Bese i-Operator ikhipha i-Workpiece esiteshini 1 bese ilayisha ucezu lokusebenza olusha;

V. umjikelezo ngokulandelana.

5. Isixazululo seRobhothi Ukucushwa Kwezisetshenziswa

| Into | Imodeli | Ubuningi | Ibhrendi | Ukuphawula | ||

| 1 | 1.1 | Umzimba werobhothi | I-HY1006A-145 | 1 Isethi | Honyen | Kubandakanya umzimba werobhothi, iKhabhinethi yokulawula, umhleli wokufundisa |

| 1.2 | Ikhabethe lokulawula amarobhothi | 1 isethi | ||||

| 1.3 | Welding amandla Umthombo | 1 Isethi | Honyen | I-Megmeet welder | ||

| 1.4 | ithangi lamanzi | 1 Isethi | Honyen | |||

| 1.5 | Ukupholisa amanzi Welding Torch | 1 Isethi | Honyen | |||

| 2 | 1 Isibonisi se-eksisi | HY4030 | 2 Setha | Honyen | 2.5m, 300kg umthwalo, 1.5KW ukalwe okukhipha amandla | |

| 3 | Isiteshi sokulawula ugesi | 2 Setha | Honyen | |||

| 4 | Ukwakhiwa kwesistimu, ukuhlanganiswa nokuhlela | 1 Isethi | Honyen | |||

| 5 | Ukuphepha kocingo | 1 Isethi | Honyen | Ongakukhetha | ||

6. Umsebenzi Oyinhloko Ukuze kuqinisekiswe ikhwalithi yokushisela nokusebenza kahle, isistimu yerobhothi ifakwe umsebenzi ophelele wokuzivikela kanye ne-arc welding database.Imisebenzi esemqoka yilena elandelayo:

Qalisa kabusha indlela yokuqala: lapho ukugeleza kwegesi yesihlangu kungavamile, i-welding wire idliwe futhi imisiwe okwesikhashana ngesikhathi sokushisela, umyalo othi "qhubeka u-welding" ungabizwa ngokuqondile ngemva kokuxazulula izinkinga, futhi i-robot ingaqhubeka ngokuzenzakalelayo i-welding kusuka kunoma yisiphi isikhundla ukuya endaweni emisiwe.

Ukutholwa kwamaphutha nokubikezela: ngemva kokuba i-alamu yenzekile, i-Robot ithola idatha edivayisini yokulawula, iqagele izingxenye ezinephutha, futhi inikeze uhlu lwezingxenye ezinamaphutha aphezulu, ibonise ukulandelana kokushintshwa kwezingxenye kanye nokuxilongwa kukhompyutha, engabukwa esizeni nge-pendant yokufundisa.Ngaphezu kwalokho, ikhompuyutha njalo Thola idatha yokusebenza erobhothini, hlaziya idatha etholiwe, yahlulela ukuthi isimo sokusebenza kwerobhothi sijwayelekile, futhi utshele umsebenzisi ukuthi abhekane nephutha elizayo.

Umsebenzi wokulwa nokushayisana: lapho ithoshi yokushisela irobhothi yenza ukuphahlazeka kwezinto zangaphandle, idivayisi yerobhothi evimbela ukushayisana isebenza ukuvikela iTorch yokushisela nomzimba werobhothi.

Isizindalwazi sochwepheshe: ngokusetha izimo zokushisela ezidingekayo ohlelweni, lolu hlelo lungaqedela ngokuzenzakalelayo ukuhlelwa kwe-weld seam kanye nokulungiswa kwemingcele ye-welding ehambisanayo.

Ukufundisa nokuhlela: bona izinhlelo ezikusayithi ngokufundisa okulengayo.

Weave welding: phakathi nenqubo yokushisela, iRobhothi ayikwazi nje ukubona uhlobo olujwayelekile lwe-welding round kanye nohlobo lwe-Z.Lokhu kusiza irobhothi ukuthi libone umsebenzi wokushisela wekhasimende ngokomumo wesiqephu somsebenzi, ukuze kwandiswe ububanzi be-weld seam ngamandla okushisela nokusebenza okuhle kokushisela.

Isibonisi sesimo: irobhothi lingabonisa isimo sokusebenza salo lonke uhlelo lwamarobhothi ngokufundisa okulengayo, okuhlanganisa isimo sokusebenza kohlelo, izinguquko zepharamitha yenqubo yokushisela, izinguquko zepharamitha yesistimu, isikhundla samanje serobhothi, amarekhodi omlando wokubulawa, amasignali okuphepha, amarekhodi e-alamu, njll., ukuze amakhasimende akwazi ukuqonda okufika ngesikhathi isimo sohlelo lwamarobhothi futhi uvimbele izinkinga kusenesikhathi.

Okokufaka / amafayela okukhiphayo: Amafayela esistimu yerobhothi namafayela ohlelo ohlelweni lwamarobhothi angagcinwa ekhadini le-SD ngaphakathi kwesilawuli serobhothi, futhi angalondolozwa kumishini yangaphandle.Izinhlelo ezibhalwe isofthiwe yokuhlela engaxhunyiwe ku-inthanethi nazo zingalayishwa kusilawuli se-Robot, Lokhu kusiza amakhasimende ukuthi agcine amafayela esistimu njalo, Uma kunenkinga ohlelweni lwamarobhothi, Lezi zipele zingabuyiselwa ukuze kuxazululwe izinkinga zerobhothi.

7, Ukwethulwa Kwezisetshenziswa I-HY1006A-145 iyirobhothi elisebenza kahle kakhulu elinomsebenzi okhaliphile.Ilungele ukushisela okuvikelwe kwegesi nokusika izicelo.Izici zayo isisindo esincane kanye nesakhiwo esihlangene.

Ngezinhlelo zokusebenza zokushisela i-arc, i-Honyen iklame ngempumelelo isisindo esilula nengalo ehlangene, engagcini nje ngokuqinisekisa ukwethembeka kwangempela, futhi ibona nokusebenza kwezindleko ezinhle kakhulu.

I-Honyen yamukela ubuchwepheshe be-servo obuthuthuke kakhulu, obungathuthukisa isivinini sokunyakaza nokunemba kwerobhothi, inciphise ukungenelela komsebenzisi, futhi ithuthukise ukusebenza kahle kokushisela nokusika igesi okuvikelwe.

| I-eksisi | Inkokhelo | Ukuphindaphinda | Umthamo wamandla | Imvelo | Isisindo | Ukufakwa |

| 6 | 10 | 0.08 | 6.5KVA | 0~45℃20~80%RH(Akukho Umswakamo) | 300kg | Umhlaba/Uphahla |

| Ibanga Lokunyakaza J1 | J2 | J3 | J4 | J5 | J6 | Izinga le-IP |

| ±170° | +80°~-150° | +95°~-72° | ±170° | +115°~-140° | ±220° | IP54/IP65(isandla) |

| Isivinini esikhulu J1 | J2 | J3 | J4 | J5 | J6 | |

| 158°/s | 145°/s | 140°/s | 217°/s | 172°/s | 500°/s |

Isixhumi esibonakalayo sokusebenza esigcwele sesiShayina futhi singashintshwa sibe yisiNgisi ngokusebenza okugcwele kwekhibhodi

Sekela ukuxhumana okuhlukahlukene okuhlanganisa i-interface ye-I / O, i-Modbus, i-Ethernet njll.

Sekela ukuxhumana namarobhothi amaningi nezinye izinto zokusebenza zangaphandle

Usayizi omkhulu wesikrini sokuthinta esimibalabala

Idivayisi emisiwe evimbela ukushayisana, ivikela ingalo yerobhothi futhi inciphisa ukuphazamiseka

Ukulawulwa kokunyakaza kwerobhothi kunikeza ukuhlelwa kwendlela efanele

Amakhulu ezikhwama zokusebenza ezakhelwe ngaphakathi nemisebenzi yenza ukuhlela kube lula

Ngekhadi le-SD, kulula ukwenza ikhophi yasenqolobaneni futhi ukopishe idatha

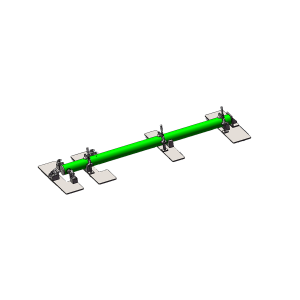

Isikhundla

I-Honyen Head-tail double support positioner esetshenziselwa ukuzungezisa ucezu lokusebenza, ukusebenzisana nerobhothi, ifinyelele isikhundla esihle sokushisela futhi izuze ukusebenza kahle kokushisela.

Umthombo Wamandla Welding

I-Megmeet Ehave cm 500h / 500 / 350 uchungechunge olugcwele umthwalo osindayo wezimboni zedijithali * CO2 / MAG / MMA umshini wokushisela ohlakaniphile

8. Ukufakwa, Ukugunyazwa kanye Nokuqeqeshwa

Ngaphambi kokulethwa, uhlelo lwamarobhothi luzohlanganiswa futhi lusebenze ngokugcwele enkampanini yethu.Ikhasimende lizoletha izingxenye zalo enkampanini yethu ukuze zifakwe isivivinyo sokushisela kanye nokwamukelwa ngaphambi kokulethwa.Ngesikhathi sokwamukelwa kwangaphambili, abasebenzisi beKhasimende bazothola ukuqeqeshwa kokuqala kwezobuchwepheshe.

Uhlelo lokufakwa kanye nezidingo zobuchwepheshe zizohanjiswa kukhasimende ezinsukwini eziyi-15 ngaphambi kokufakwa, futhi ikhasimende lizokwenza amalungiselelo afika ngesikhathi ngokwezidingo.Inkampani yethu izothumela onjiniyela ukuthi benze ukufakwa kwesistimu kanye nokugunyazwa endaweni yomsebenzisi.Ngaphansi kombandela wokuthi ikhasimende liqinisekisa ama-workpieces okusebenza anele, isikhathi kusukela ekugunyazweni kwezinhlelo, ukuqeqeshwa kwezisebenzi kuya ekukhiqizweni kwesivivinyo esikhulu ngeke sidlule izinsuku eziyi-10.Inkampani yethu iqeqesha abasebenzisi bohlelo lwamarobhothi, ukusebenza nokunakekelwa kwamakhasimende, futhi abaqeqeshwayo kufanele babe nolwazi oluyisisekelo lwekhompyutha.

Ngesikhathi sokufakwa kanye nokugunyazwa, ikhasimende lizohlinzeka ngamathuluzi adingekayo, njengemishini yokuphakamisa, i-forklift, izintambo, ukubhola komthelela, njll., futhi inikeze usizo lwesikhashana ngesikhathi sokuthulula nokufakwa.

Inkampani yethu inesibopho sokuqondisa, ukufakwa, ukugunyazwa kwemishini kanye nokuqeqesha opharetha.Inkampani yethu inesibopho sokuqeqesha nokuqeqesha ukusebenza.Umsebenzisi uzosebenzisa futhi anakekele okokusebenza ngokwawo.Okuqukethwe kokuqeqeshwa: isimiso sesakhiwo semishini, ukuxazulula inkinga kagesi okuvamile, isingeniso semiyalo eyisisekelo yokuhlela, amakhono okuhlela nezindlela zokuhlela zezingxenye ezijwayelekile, isingeniso kanye nezixwayiso zephaneli yokusebenza kwemishini, umkhuba wokusebenza kwemishini, njll.

9. Hlola nokwamukela

Ukwamukelwa kwangaphambilini kwenziwa enkampanini yethu ngokubamba iqhaza kwabasebenzi abafanelekile bazo zombili izinhlangothi.Ngesikhathi sokwamukelwa kwangaphambili, ama-workpieces azohlolwa ngokuya ngokunemba kwe-workpiece ehlinzekwe yikhasimende, Yicwecwe lokusebenza eliqeqeshiwe kuphela elizoshiselwa, bese kukhishwa umbiko wokuhlolwa wangaphambi kokwamukelwa.Ngemuva kokwamukelwa okuphelele, iRobhothi izolethwa.Ukuze kuqinisekiswe ukwamukelwa kwangaphambili, kuzohlinzekwa iziqephu zokusebenza ezi-3 zokukhiqiza okuvamile.

10.Izidingo Zemvelo Izidingo zokuphepha: igesi kanye nezingxenye ezisele ezisetshenziswa abasebenzisi kufanele zihambisane nezindinganiso zikazwelonke ezifanele.

Umthombo womoya kufanele ubekwe ngaphandle, ungabi ngaphansi kwama-15m kude nomlilo, futhi ungabi ngaphansi kwama-15m kude negesi nomoya-mpilo.Umthombo womoya kufanele ugcine izimo ezinhle zokungenisa umoya futhi ube sendaweni epholile kude nomoya.

Wonke amasekhethi egesi kufanele ahlolwe ngaphambi kokusebenzisa irobhothi.Uma kukhona ukuvuza komoya, kufanele kulungiswe ukuze kuqinisekiswe ukuthi akukho phutha.

lapho ulungisa ukucindezela nokushintsha isilinda segesi, opharetha ngeke abe nezinto zikawoyela ezandleni zakhe.

umswakama we-ambient: ngokuvamile, umswakama we-ambient ngu-20% ~ 75% RH (uma kungabikho ukufingqa);Isikhathi esifushane (phakathi nenyanga engu-1) ngaphansi kuka-95% RH (izikhathi ezingenakho ukufingqa).

umoya ocindezelwe: 4.5 ~ 6.0 kgf / cm2 (0.45-0.6mpa), uwoyela wokuhlunga namanzi, ≥ 100L / min

Isisekelo: amandla kakhonkolo amancane angama-C25, futhi ubukhulu obuncane besisekelo bungama-400 mm

ukudlidliza: gwema umthombo wokudlidliza

ukunikezwa kwamandla kagesi: ukuphakelwa kwamandla azo zonke izisetshenziswa zikagesi neze-elekthronikhi ezikhiqiziwe zisebenzisa i-50Hz (± 1) kanye ne-380V (± 10%) i-voltage ye-AC yezigaba ezintathu ukuze kuqinisekiswe ukusekelwa okuyisisekelo kokuphakelwa kukagesi.

Amasevisi esayithi ahlinzekwa ngamakhasimende:

wonke amalungiselelo adingekayo ngaphambi kokulethwa, njengesisekelo, umsebenzi we-welding odingekayo, ukulungisa amathuluzi asizayo, njll.

ukuthulula nokuthutha endaweni yekhasimende.

11. Iwaranti kanye nesevisi yangemuva kokudayiswa Isikhathi sewaranti yomthombo wamandla e-weld yizinyanga eziyi-12.

Isikhathi sewaranti yomzimba werobhothi izinyanga eziyi-18.

Esimeni lapho ukwehluleka noma ukulimala ngaphansi kokusetshenziswa okujwayelekile futhi okokusebenza kungaphakathi kwesikhathi sewaranti, inkampani yethu ingalungisa noma ishintshe izingxenye zamahhala EXW (ngaphandle kwezindleko ezidliwayo, imikhiqizo yokunakekela, amashubhu okuphepha, izibani zezinkomba nokunye okusebenzisekayo okukhethwe inkampani yethu ngokukhethekile).

Ezingxenyeni ezisengozini ngaphandle kwewaranti, inkampani yethu ithembisa impilo evamile yesevisi kanye nentengo yokuhlinzeka yezingxenye ezisengozini, futhi imishini inomzila oqinile wokunikezela wemishini iminyaka emihlanu.

Esikhathini sewaranti, inkampani yethu izoqhubeka nokuhlinzeka ngesevisi ekhokhelwa impilo yonke futhi inikeze ukwesekwa okuphelele kwezobuchwepheshe kanye nezinsiza ezidingekayo.

12. Ukulethwa Kwemibhalo Enamathiselwe Imidwebo yokufaka: imidwebo yokwakha isisekelo semishini kanye nemidwebo yokufaka imishini

◆ imidwebo yokuklama: imidwebo yesakhiwo nemishini

◆ Imanuwali: imanuwali yokusebenza kwemishini, imanuwali yokulungisa kanye nebhukwana lokusebenza kwerobhothi

◆ izesekeli: uhlu lokulethwa, isitifiketi kanye nekhadi lewaranti.