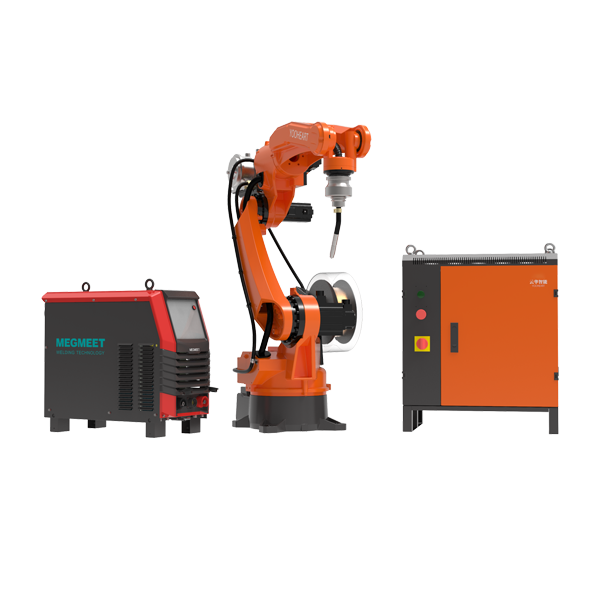

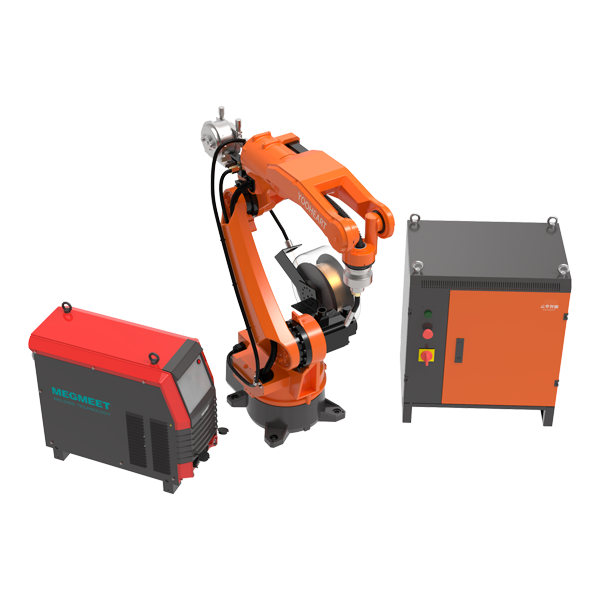

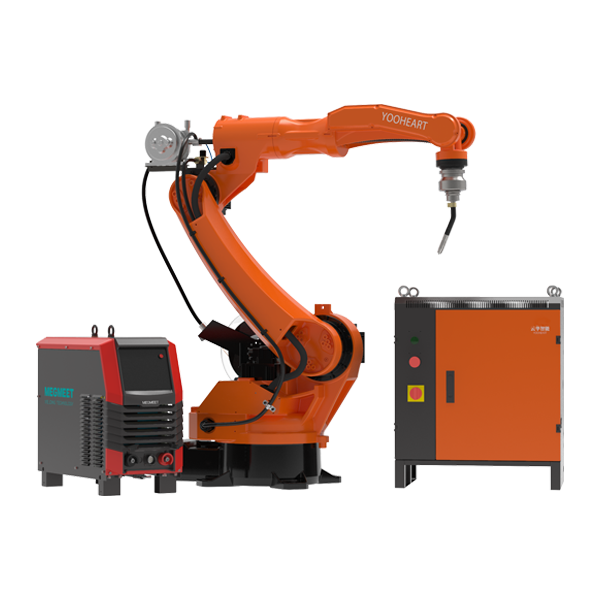

I-6 Axis Arc welding Robot 1450mm ubude bengalo Nomthombo wamandla wokushisela we-Megmeet

-Irobhothi umzimba: HY1006A-145

-Umthombo wamandla we-Weld: I-Megmeet Ehave CM 350AR

-Ithoshi lokushisela: Ithoshi lokupholisa igesi ye-Loyee Noma ithoshi lokupholisa le-Honyen Gas

-Isiphakeli socingo esine-roller yocingo engu-0.8/1.0

-LNC isilawuli kanye Panel

-I-Wooden Packing yokuthumela ngaphandle

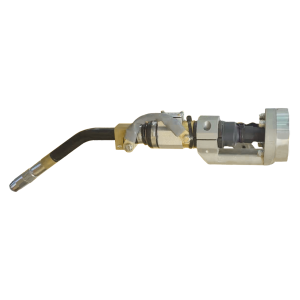

I-Optional Welding Torch

I-Loyee Robot Welding Torch

I-torque ephezulu nekhebuli yokumelana nokugqoka

Ukusungulwa kwelungelo lobunikazi lobuchwepheshe bokumelana nokushayisana

Isivinini esikhulu nokunemba kabusha kwedivayisi evimbela ukushayisana\

Ububanzi Bentambo: 0.8 ~ 1.0mm

I-Honyen Robot Welding Torch

I-torque ephezulu nekhebuli yokumelana nokugqoka

Ukusungulwa kwelungelo lobunikazi lobuchwepheshe bokumelana nokushayisana

Isivinini esiphezulu nokunemba kabusha kwedivayisi emelene nokushayisana

Ububanzi Bentambo: 0.8 ~ 1.0mm

Ezinye Izisetshenziswa Zokumisa

I-Megmeet Ehave CM 350AR

| into | Ukucaciswa |

| Imodeli | I-Megmeet Ehave CM 350 |

| Amandla kagesi | 3*380V±25% 30--80HZ |

| Amandla Okufaka Alinganiselwe | 13.5KVA |

| Isici samandla | 0.94 |

| Ukusebenza kahle | 86% |

| I-OCV elinganiselwe | 63.3V |

| Okukhiphayo Okukaliwe kwamanje | 30A-400A |

| I-Voltage Ephumayo Elinganiselwe | 12V-38V |

| I-Wire Dia | 0.8mm/1.0mm/1.2mm |

| Izinga le-IP | IP23S |

| Ibanga le-Insulation | H |

| Imodi Yokupholisa | Ukupholisa umoya |

| Ubukhulu (L*W*H) | 620mm*300mm*480mm |

| Isisindo | 48kg |

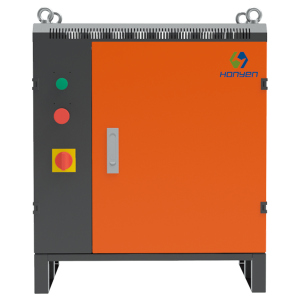

Ikhabhinethi yokulawula

| Into | Ukucaciswa |

| Usayizi weKhabhinethi | 603mm*502mm*760mm |

| Isisindo | 55kg |

| Izinga le-IP | IP54/IP65 |

| Izinga lokushisa | Ukusebenza: 0-45 ℃Isitoreji: -10 ~ 60 ℃ |

| Umswakama | Ubukhulu obungu-90% (Akukho-condensation |

| Amandla kagesi | 3*380V 50~60HZ |

| Uhlelo Lokupholisa | Ukupholisa abalandeli |

| Ubude bekhebula | Izinga: 5M, Max:12M |

| Imodi Yokuxhumana | Pulse |

I-wire feeder

Ukusabela Ngesikhathi Ngokuphakelayo kwentambo nokubuya

Ukuphakelwa kwezintambo okushelelayo, Ukungaqoqi nokushelela

Ikhono Eliqinile Lokulwa Nokuphazamiseka

Isicelo Sekhasimende

I-Baby Carriage Robot Working Station

Steel Ladder Robot Working Station

Izithombe Embonini Yabathengi

Amapharamitha weRobhothi Welding

| I-eksisi | Inkokhelo | Ukuphindaphinda | Umthamo wamandla | Imvelo | Isisindo | Ukufakwa |

| 6 | 6kg | 0.08 | 6.5KVA | 0 ~ 45℃ 20~80%RH(Akukho Ukujiya) | 170kg | Umhlaba/Uphahla |

| Ibanga Lokunyakaza J1 | J2 | J3 | J4 | J5 | J6 | Izinga le-IP |

| ±170° | +80°~-150° | +95°~-72° | ±170° | +115°~-140° | ±220° | IP54/IP65(isandla) |

| Isivinini esikhulu J1 | J2 | J3 | J4 | J5 | J6 | |

| 158°/s | 145°/s | 140°/s | 217°/s | 172°/s | 500°/s |

Imibukiso

I-Beijing Essen Welding & Cutting Fair

I-China International Industry Fair – CIIF

I-China International Machine Tool Show

I-FQA

Q. Ithini imakethe engukhiye yerobhothi lakho?

A. Manje irobhothi lethu lingasebenzela izimoto, isakhiwo sensimbi, umshini wepulazi, ifenisha yensimbi, amandla amasha, ukugcinwa nokulethwa, umshini wobunjiniyela, okokusebenza ngokomzimba, umshini wezilwane, isithuthuthu njll.

Q. hlobo luni lwesevisi ongayinikeza?

A. Ngokuqondene nezicelo, ukushisela, ukunikeza, ukukhetha nokubeka, ukudweba, ukufakwa kwe-palletizing, ukusika i-laser, i-laser welding, ukusika i-plasma nokunye.

Q. Hlobo luni lwenqubo yokushisela onalo?

A. Ngezicelo zokushisela, singanikela nge-argon arc welding, i-mag welding, i-gas shield welding, i-tig self fusion welding, i-tig wire feeding welding.

Q. Iluphi uhlobo lomthombo wamandla olunikeza irobhothi?

A. Manje ngokulungiselelwa okujwayelekile: I-Megmeet ne-AoTai.

Q. Ingabe unayo isistimu yakho yokulawula?

A. Yebo, kunjalo.Akukhona nje ukuthi sinesistimu yokulawula, izingxenye ezibaluleke kakhulu zerobhothi: i-reducer iyakhiqizwa.Yingakho sinenani elincintisana kakhulu.

Ngemva kokudayiswa Service

Isikhathi sokuqinisekisa ikhwalithi yomkhiqizo unyaka owodwa kusukela ngedethi yokulethwa.Uma irobhothi elishiselayo lihluleka ngesikhathi sewaranti (ngaphandle kokwehluleka okubangelwa ukusetshenziswa okungafanele komthengi), i-Honyen Robot izoba nesibopho sokuyilungisa kuze kube yilapho ishintsha imishini emisha(EXW), futhi izindleko ezidalekile zizothwalwa ngu-Honyen(izindleko zokudiliva) ayifakiwe);Esimeni lapho okokusebenza kungasebenzi okubangelwa ukusetshenziswa ngendlela engafanele komthengi, ifekthri yakwa-Honyen izoba nesibopho sokunakekela nokukhokhisa izingxenye ezishintshayo.

Ngesikhathi sewaranti, uma imishini yehluleka, abasebenzi benkonzo yezobuchwepheshe bomthengisi bazolungisa amathuluzi adingekayo kanye nezingxenye ezisele kungakapheli amahora ayi-8 ngemuva kokuqinisekisa ukwehluleka kwemishini nabasebenzi abasebenza endaweni kanye nokulungiswa, futhi bafike endaweni phakathi kwamahora angama-24 futhi qala ukulungiswa, ukuxazulula inkinga (ngaphandle kwesizathu sebanga).

Njalo ngonyaka, ngokusekelwe esimweni sangempela semakethe kanye nezidingo zabasebenzisi besifunda, inkampani njalo yenza izimpindelo zesevisi yesifunda mahhala (ngaphandle kwemali yesevisi yokushintsha izingxenye nezingxenye).

Ngokuhambisana nemikhiqizo ethengiswa yinkampani yethu kanye nezingxenye ezijwayelekile kanye nezingxenye ezisebenzisekayo zesethi ephelele yamarobhothi wokushisela, siqinisekisa ukuhlinzeka ngezinsizakalo ezijwayelekile.Izingxenye ezisele zisendaweni yokugcina impahla (ngaphandle kwemikhiqizo ekhethekile).Izingxenye ezivamile kanye nezingxenye ezisetshenziswayo ziqinisekisiwe ukuthi zizonikezwa ngesikhathi ngokuvumelana ne-oda, futhi izingxenye ezikhethekile zi-odwa ngokuvumelana nenkontileka okuvunyelwene ngayo yizinhlangothi zombili.

Ngemva kokuphela kwesikhathi sewaranti, uma okokusebenza kwehluleka, Umthengisi uzoqhubeka nokuhlinzeka ngamasevisi okunakekela umthengi, akhokhise izindleko zokushintsha izisekeli, futhi akhokhise inhlawulo yesevisi eyisisekelo yesevisi yendlu ngendlu.

Ngokwesidingo somthengi, Umdayisi uzoba nesibopho sokuthuthukisa impilo yonke yamahhala yesofthiwe yemishini esetshenziswa umthengi werobhothi lokushisela iMig.