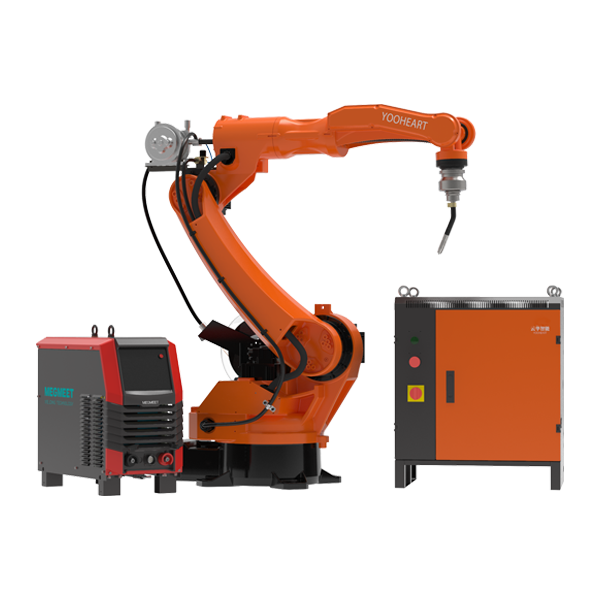

Bingo TIG umshini wokushisela

Sibuke Sisebenza!

Imodeli Edumile Elandelayo

Umthombo wamandla wokushisela we-TIG, imodeli yeManuwali neRobhothi, Sekela iphrothokholi yokuxhumana ehlukene

I-WSME 315/400/500/630

Umshini wokushisela we-AC kanye ne-DC pulse argon arc

Imisebenzi:

I-AC yamanje ye-TIG eqhubekayo, i-AC pulse TIG, i-DC eqhubekayo ye-TIG yamanje, i-AC pulse TIG, i-welding ye-mental-arc welding.

Imboni yohlelo lokusebenza:

I-Aerospace, ukuhlukaniswa komkhathi, imboni ye-petrochemical, isishintshi sokushisa, ifenisha ye-aluminium nokukhanya kwebhayisikili.

Izici:

Iphaneli yokusebenza enesakhiwo esinengqondo, imisebenzi ecebile nokusebenza okulula;

◆Ipharamitha yokushisela ingahlelwa kahle;

◆Imvamisa ye-AC nobubanzi bokuhlanza kungalungiswa ngokuzimela ukuze kuhlangatshezwane nezidingo zenqubo yokushisela yemikhiqizo ehlukene ye-aluminium;

◆ Inesiteleka se-arc esilula, i-arc kagesi ezinzile kanye ne-weld pool elawulwa kalula;

◆I-argon arc welding ingavikela isibhamu sokushisela ekuncipheni kwamanzi;

◆I-welding current ingalawuleka kude;

◆Ukungena kwe-weld kanye nobubanzi be-weld obudingekayo ngokuhlanganyela kwe-weld kanye nenani le-waveform ingatholakala ngokulungiswa kwe-pulse yamanje, imvamisa yomfutho, isilinganiso somsebenzi, i-alternating current, i-AC frequency, i-proportion yokuhlanza kanye ne-AC bias ratio lapho i-AC argon. i-arc welding isetshenziselwa ukwelula impilo yesevisi, isebenza ngokukhethekile ekushiseleleni okuzenzakalelayo kanye nokushisela amarobhothi.

| Imodeli | I-WSME- -315R | I-WSME-400 | I-WSME-500 | I-WSME-630 |

| I-voltage yokufaka elinganiselwe / imvamisa | Isigaba sesithathu380V(+/-)10% 50Hz | |||

| Umthamo wokufaka olinganiselwe (KVA) | 12.1 | 17.1 | 25.7 | 34.7 |

| Okokufaka okulinganiselwe okwamanje (A) | 18.5 | 26 | 39 | 53 |

| Isilinganiso sokusimama komthwalo (%) | 60 | 60 | 60 | 60 |

| I-voltage engekho yokulayisha (V) | 63 | 70 | 79 | 79 |

| Ibanga lamanje lokuphumayo (A) | 5~315 | 5-400 | 20~500 | 20-630 |

| I-arc yokuqala yamanje (A) | 10~315 | 10-400 | 20~500 | 20-630 |

| Isilinganiso esiphezulu (A) | 5~315 | 10-400 | 20~500 | 20-630 |

| I-arc stop current (A) | 5~315 | 10-400 | 20~500 | 20-630 |

| Isikhathi sangaphambi kokugeleza (S) | 0.1~15 | |||

| Isikhathi sokusalela sokumisa igesi (S) | 0.1~20 | |||

| Imvamisa ye-Pulse (Hz) | 0.2~20 | |||

| Umsebenzi we-Pulse (%) | 1~100% | |||

| I-AC frequency (Hz) | 20~200 | 20~200 | 20~100 | 20~100 |

| Isitayela se-arc somshayeli we-TIG | Isiqephu se-HF | |||

| I-Trust current (A) | 30-315 | 50-400 | 50-500 | 50-630 |

| Imodi yokupholisa | Ukupholisa amanzi | |||

| Ibanga le-insulation | H/B | |||

I-WSM 315/400/500

Inverted DC pulse argon arc umshini wokushisela

Imisebenzi:

I-DC yamanje ye-TIG, i-DC pulse TIG, i-welding yensimbi ye-arc manual.

Imboni yohlelo lokusebenza:

Imboni ye-Petrochemical, umkhumbi wengcindezi, ukwakhiwa kwamandla kagesi, umkhumbi, ibhayisikili, amandla enuzi kanye nokubeka amapayipi.

Izici:

◆ Iphaneli yokusebenza enesakhiwo esiphusile, imisebenzi ecebile kanye nokusebenza okulula;

◆Amapharamitha afana nokukhuphuka kancane kanye nokwehla kancane kwamandla kagesi, imvamisa yomfutho, isilinganiso somsebenzi, isikhathi sokuphakelwa kwegesi okuthuthukisiwe kanye nokutholakala kwegesi esilele kungase kumiswe kusengaphambili ngokunembile;

◆I-welding ye-arc ye-metal-arc ingakwazi ukulungisa amandla kagesi we-arc eshayayo kanye ne-thrust, ngokushaya okulula kwe-arc futhi ivimbele ukunamathela kwenduku yokushisela;

◆I-argon arc welding ingavikela isibhamu sokushisela ekuncipheni kwamanzi;

◆ Inezinyathelo ezimbili kanye nezinyathelo ezine zokulawula izindlela zokushisela;

◆Incane futhi ilula futhi ilungele ukunyakaza;

◆I-current kanye ne-voltage ingaboniswa kanyekanye.I-welding current ingahlelwa ngokunembile;

I-◆TIG ingakhetha indlela yokuphakama okuphezulu kwe-arc striking.

| Imodeli | I-WSM-315 | I-WSM-400 | I-WSM-500 | ||

| I-voltage/imvamisa yokufaka elinganiselwe | Isigaba sesithathu380V(+/-)10% 50Hz | ||||

| Umthamo wokufaka olinganiselwe (KVA) | 11.2 | 17.1 | 23.7 | ||

| Okokufaka okulinganiselwe okwamanje (A) | 17 | 26 | 36 | ||

| Isilinganiso sokusimama komthwalo (%) | 60 | 60 | 60 | ||

| I-DC constant current Welding current (A) | 5~315 | 5-400 | 5-500 | ||

| I-DC pulse | Isilinganiso esiphezulu (A) | 5~315 | 5-400 | 5-500 | |

| Isisekelo samanje (A) | 5~315 | 5-400 | 5-500 | ||

| Umsebenzi we-Pulse (%) | 1~100 | ||||

| Imvamisa ye-Pulse (Hz) | 0.2~20 | ||||

| I-TIG | I-arc yokuqala yamanje (A) | 10-160 | |||

| I-arc stop current (A) | 5~315 | 5-400 | 5-500 | ||

| Isikhathi sangaphambi kokugeleza (S) | 0.1-15 | ||||

| Isikhathi sokusala kwegesi- -ukumisa (S) | 0.1~20 | ||||

| Isitayela se-arc somshayeli we-TIG | Isiqephu se-HF | ||||

| I-arc yesandla yokushisela i-Welding yamanje (A) | 30~315 | 40-400 | 50~500 | ||

| Imodi yokupholisa | Ukupholisa amanzi / Ukupholisa umoya | ||||

| Ibanga lokuvikela igobolondo | IP21S | ||||

| Ibanga le-insulation | H/B | ||||

I-WSM -S/YS 400

Inverted DC pulse argon arc umshini wokushisela

| Imodeli | I-WSM-400S/YS | ||

| I-voltage/imvamisa yokufaka elinganiselwe | Isigaba sesithathu380V(+/-)10% 50Hz | ||

| Umthamo wokufaka olinganiselwe (KVA) | 17.1 | ||

| Okokufaka okulinganiselwe okwamanje (A) | 26 | ||

| Isilinganiso sokusimama komthwalo (%) | 60 | ||

| I-DC constant current Welding current (A) | 5-400 | ||

| I-DC pulse | Isilinganiso esiphezulu (A) | 5-400 | |

| Isisekelo samanje (A) | 5-400 | ||

| Umsebenzi we-Pulse (%) | 1~100 | ||

| Imvamisa ye-Pulse (Hz) | 0.2~20 | ||

| Isikhathi sangaphambi kokugeleza (S) | 0.1-15 | ||

| Isikhathi sokusala kwegesi- -ukumisa (S) | 0.1~20 | ||

| Isitayela sokusebenza se-arc yokumisa yamanje | Izinyathelo ezimbili, Izinyathelo ezine | ||

| Isitayela se-arc somshayeli we-TIG | Isiqephu se-HF | ||

| Imodi yokupholisa | Ukupholisa amanzi / Ukupholisa umoya | ||

| Ibanga lokuvikela igobolondo | IP21S | ||

| Ibanga le-insulation | H/B | ||

Imisebenzi:

I-DC yamanje ye-TIG, i-DC pulse TIG.

Imboni yohlelo lokusebenza:

Imboni ye-Petrochemical, umkhumbi wengcindezi, ukwakhiwa kwamandla kagesi, umkhumbi, ibhayisikili, amandla enuzi kanye nokubeka amapayipi.

Izici:

◆ Iphaneli yokusebenza enesakhiwo esiphusile, imisebenzi ecebile kanye nokusebenza okulula;

◆Amapharamitha afana nokukhuphuka kancane kanye nokwehla kancane kwamandla kagesi, imvamisa yomfutho, isilinganiso somsebenzi, isikhathi sokuphakelwa kwegesi okuthuthukisiwe kanye nokutholakala kwegesi esilele kungase kumiswe kusengaphambili ngokunembile;

◆I-welding ye-arc ye-metal-arc ingakwazi ukulungisa amandla kagesi we-arc eshayayo kanye ne-thrust, ngokushaya okulula kwe-arc futhi ivimbele ukunamathela kwenduku yokushisela;

◆I-argon arc welding ingavikela isibhamu sokushisela ekuncipheni kwamanzi;

◆ Inezinyathelo ezimbili kanye nezinyathelo ezine zokulawula izindlela zokushisela;Incane futhi ilula futhi ilungele ukunyakaza;

◆I-current kanye ne-voltage ingaboniswa kanyekanye.I-welding current ingahlelwa ngokunembile;

I-◆TIG ingakhetha indlela yokuphakama okuphezulu kwe-arc striking;

◆Isistimu yokuphakelwa kwezintambo eqinile eyakhelwe ngaphakathi inamamenyu omsebenzi anothile wokuphakela ngocingo, okungahlangabezana nezidingo zenqubo ehlukene;

◆Izinga lokuphakelayo kwezintambo kanye nokushaya kwenhliziyo okufanayo ngokuzenzakalelayo.

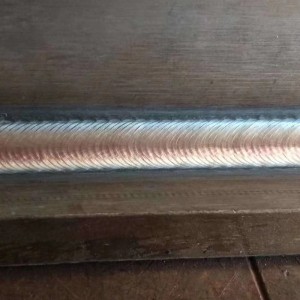

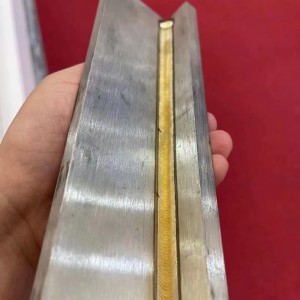

Ukucatshangelwa kwe-Welder

Lapho amapuleti ensimbi amabili anogqinsi oluhlukene ehlanganiswa ndawonye, ukuze kugwenywe ukugxiliswa kwengcindezi okukhulu okubangelwa ukushintsha okusheshayo kwengxenye ephambanayo, unqenqema lwepuleti elishubile livame ukuncishiswa kancane kancane ukuze kuzuzwe ukujiya okufanayo emaphethelweni amabili.Amandla amile kanye nokukhathala kwamalunga ezinqe aphakeme kunamanye amalunga.Ukuze kuxhunywe ngaphansi kokushintshana, imithwalo yokushaqeka noma ukusebenza endaweni yokushisa ephansi kanye nemikhumbi yokucindezela okukhulu, ukushisela amalunga ezinqe ngokuvamile kuyathandwa.Ukulungiswa kwangaphambili kwe-welding ye-lap joint kulula, umhlangano ulula, futhi i-welding deformation kanye nokucindezeleka okusalayo kuncane, ngakho-ke kuvame ukusetshenziselwa ukufakwa kwamalunga nezakhiwo ezingabalulekile esizeni.Ngokuvamile, ama-lap joints awafaneleki ukusebenza ngaphansi kwezimo ezifana nemithwalo eshintshanayo, imidiya ebolayo, izinga lokushisa eliphezulu noma eliphansi.Ukusetshenziswa kwama-T-joints kanye namakhoneni ahlangene kuvame ukubangelwa izidingo zesakhiwo.Izici zokusebenza ze-fillet welds ezingaphelele kumajoyinti e-T zifana nokushisela kwe-fillet kumajoyinti ethangeni.Lapho i-weld i-perpendicular isiqondiso samandla angaphandle, iba yi-fillet weld yangaphambili.Ngalesi sikhathi, ukuma kwe-weld surface kuzodala amazinga ahlukene okugxilisa ukucindezeleka;ukucindezeleka kwe-penetration fillet weld kufana ne-butt joint.

Kungani Khetha thina

SIYADALA

I-BINGOucwaninga njalo futhi athuthukeubuchwepheshe be-welding obuhlakaniphileake imishini yokushisela ngaphezuluhamba emhlabeni jikelele

SIYAKUSHIYA

Manje isithintekile futhi isithandwangamazwe amaningiesikhathini esizayo

SIYAMANGALISA

Sizotshala izinsiza ezengeziwe kuzor & d okuqhubekayo kanye nokukhiqizwaqhubekela phambiliungayeki