Ukusetshenziswa kwamarobhothi okushisela kufanele kulawule ngokuqinile ikhwalithi yokulungiselela izingxenye futhi kuthuthukise ukunemba komhlangano wokushisela.Izinga eliphezulu, usayizi we-groove kanye nokunemba komhlangano wezingxenye kuzothinta umphumela wokulandela umphetho we-welding.Izinga lokulungiswa kwezingxenye kanye nokunemba kokuhlanganiswa kwe-weldment kungathuthukiswa kusuka kulezi zici ezilandelayo.

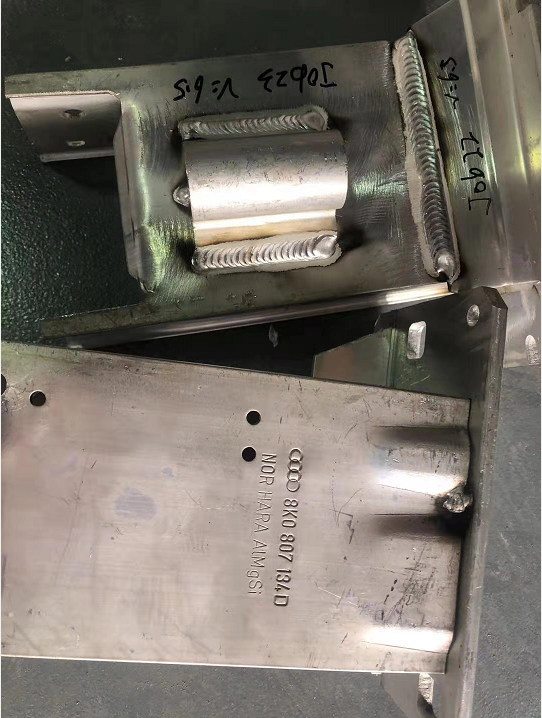

(1) Hlanganisa inqubo yokushisela ekhethekile yamarobhothi okushisela, futhi wenze imithetho eqinile yenqubo ngosayizi wezingxenye, imisele yokushisela, nobukhulu bokuhlanganisa.Ngokuvamile, ukubekezelelwa kwezingxenye kanye nobukhulu begroove kulawulwa ngaphakathi kuka-±0.8mm, futhi iphutha lobukhulu bomhlangano lilawulwa phakathi kuka-±1.5mm.Amathuba okukhubazeka okushisela njengama-pores kanye nama-undercuts ku-weld angancishiswa kakhulu.

(2) Sebenzisa amathuluzi okuhlanganisa anembe kakhulu ukuze uthuthukise ukunemba komhlangano wokushisela.

(3) I-Welding seams kufanele ihlanzwe, ingabi namafutha, i-rust, i-welding slag, i-slag yokusika, njll, kanye nama-primers athengiswayo avunyelwe.Uma kungenjalo, kuzothinta izinga lempumelelo lokuvutha kwe-arc.I-Tack welding iyashintshwa isuka ekushiseleleni i-electrode iye kwi-gas shielded welding.Ngasikhathi sinye, izingxenye zokushisela amabala ziyapholishwa ukuze kugwenywe ama-slag crusts asele noma ama-pores ngenxa ye-tack welding, ukuze kugwenywe ukungazinzi kwe-arc ngisho ne-spatter.

Isikhathi sokuthumela: Sep-11-2021