Okokuqala, indlela yokuphephetha yegesi yokuvikela

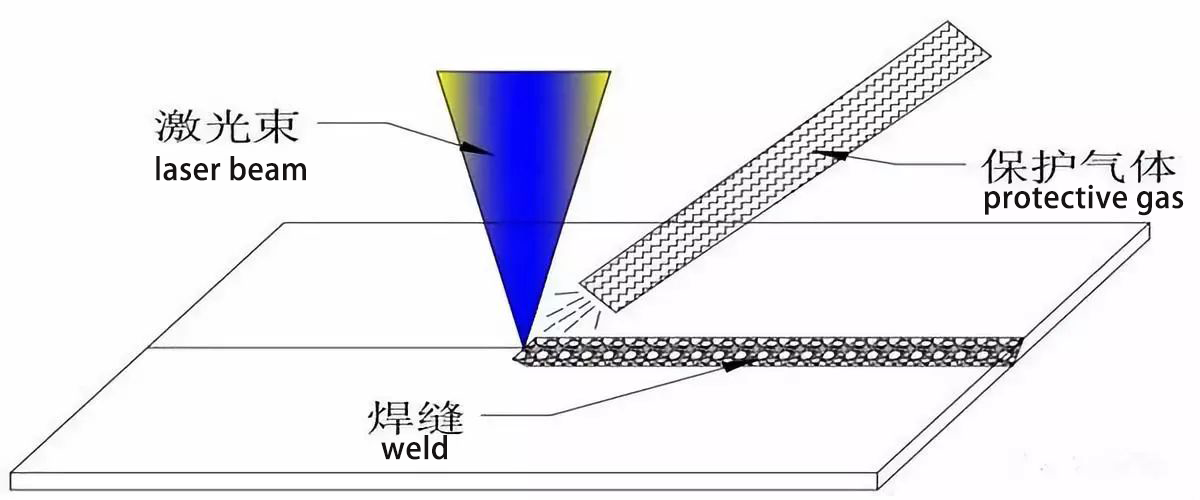

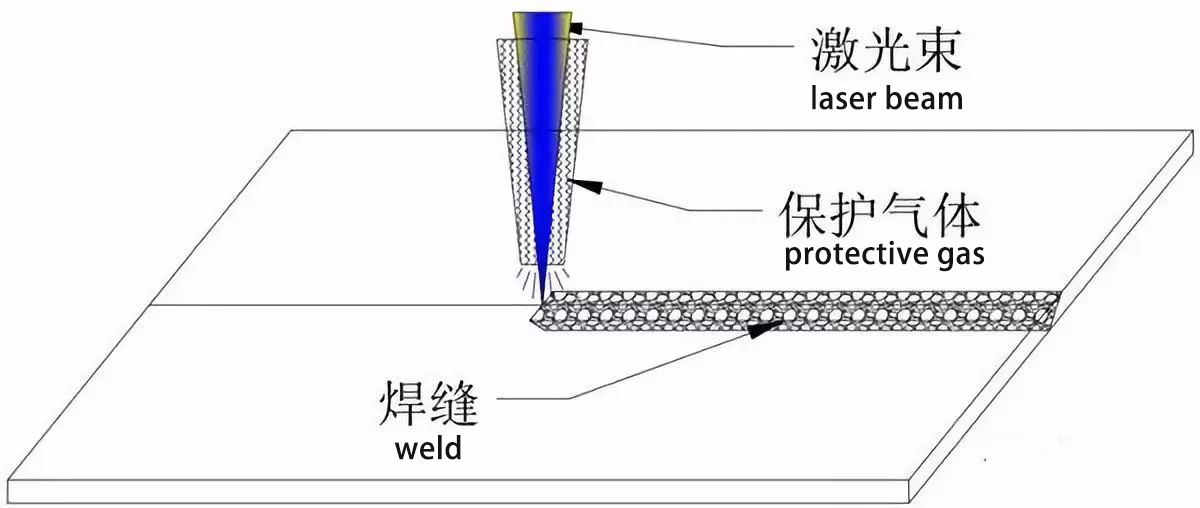

Njengamanje, kunezindlela ezimbili eziyinhloko zokuphefumula kwegesi evikelayo: enye igesi evikelayo ye-paraxial side-blowing, njengoba kuboniswe kuMfanekiso 1; Enye igesi yokuvikela i-coaxial.Ukukhethwa okuqondile kwezindlela ezimbili zokushaywa kucatshangelwa ezicini eziningi.Ngokuvamile, kunconywa ukusebenzisa ukuvuthela ohlangothini ukuze uvikele igesi

i-paraxial blowing igesi yokuvikela

igesi evikelayo ephephetha i-coaxial

igesi evikelayo ephephetha i-coaxialOkwesibili, isimiso sokukhetha imodi yokuvikela ephephetha igesi

Okokuqala, kufanele kucace ukuthi lokho okubizwa ngokuthi i-weld "oxidized" yigama elivamile kuphela.Ngokwethiyori, kubhekiselwa ekuphenduleni kwamakhemikhali phakathi kwe-weld kanye nezithako eziyingozi emoyeni, okuholela ekuwohlokeni kwekhwalithi ye-weld.Kuvamile ukuthi insimbi yokushisela isabelane nomoya-mpilo, i-nitrogen ne-hydrogen emoyeni ezingeni lokushisa elithile.

Ukuvimbela i-weld ekubeni "i-oxidized" ukunciphisa noma ukugwema ukuthintana kwezithako ezinjalo eziyingozi ngensimbi ye-weld esimweni sokushisa okuphezulu.Lesi simo sokushisa okuphezulu akusona nje insimbi ye-pool encibilikisiwe, kodwa yonke inqubo yesikhathi kusukela esikhathini lapho insimbi ye-weld incibilika ekuqinisweni kwensimbi ye-pool futhi izinga lokushisa layo liyancipha libe lokushisa elithile elingezansi.

Okwesithathu, sithatha isibonelo.

Isibonelo, i-titanium alloy welding, lapho izinga lokushisa lingaphezu kuka-300 ℃ lingamunca ngokushesha i-hydrogen, ngaphezu kuka-450 ℃ ingakwazi ukumunca umoya-mpilo ngokushesha, ngaphezu kuka-600 ℃ ingakwazi ukumunca ngokushesha i-nitrogen, ngakho-ke i-titanium alloy welding seam emva kokuqina nokunciphisa izinga lokushisa libe ngu-300 ℃. ngezansi kwalesi sigaba kudingeka kube nomphumela wokuvikela osebenzayo, ngaphandle kwalokho "uzokwenziwa nge-oxidized".

Kusukela encazelweni engenhla akunzima ukuyiqonda, ukuvikelwa kwegesi evunguzayo akudingi nje kuphela ngesikhathi esifanele ukuvikela i-weld pool encibilikisiwe, futhi kudingeka ukuthi ifakwe endaweni eyiqhwa nje yokuvikela, ngakho-ke ngokuvamile yamukele i-paraxial ekhonjiswe kumdwebo we-1 side protective. igesi, ngoba le ndlela ehlobene nezindlela zokuvikela uhla lokuvikela lwendlela yokuvikela i-coaxial yesibalo sesi-2 ibanzi kakhulu,Ikakhulukazi indawo yokushisela esanda kuqiniswa inesivikelo esingcono.

I-Paraxial side evuthela izicelo zobunjiniyela, akuyona yonke imikhiqizo engasebenzisa indlela yegesi yokuvikela ephephetha uhlangothi lwe-shaft side, kweminye imikhiqizo ethile, ingasebenzisa kuphela igesi yokuvikela i-coaxial, izidingo ezithile ezivela esakhiweni somkhiqizo kanye nokukhetha okuhlosiwe kwefomu elihlanganyelwe.

Okwesine, ukukhethwa kwemodi ethile yokuvikela ephephetha igesi

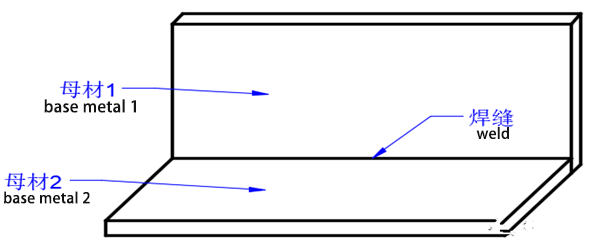

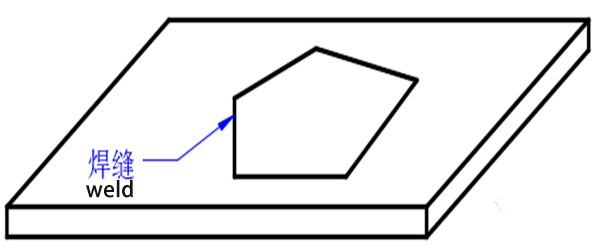

1. Ama-welds aqondile

Njengoba kuboniswe kuMfanekiso 3, ukuma kwe-weld yomkhiqizo kuwumugqa oqondile, futhi ifomu elihlangene lingaba ilunga le-butt, i-lap joint, ilunga lekhona elingalungile noma ijoyinti lokushisela eleqayo.Ngalolu hlobo lomkhiqizo, kungcono ukusebenzisa indlela yegesi yokuvikela ohlangothini lwe-sideshaft njengoba kukhonjisiwe kuMfanekiso 1.

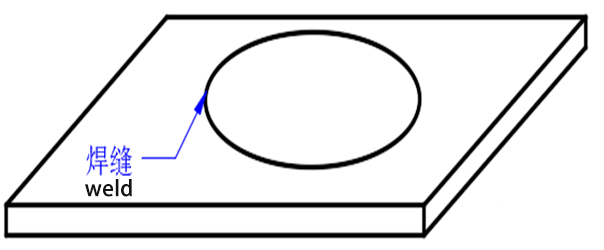

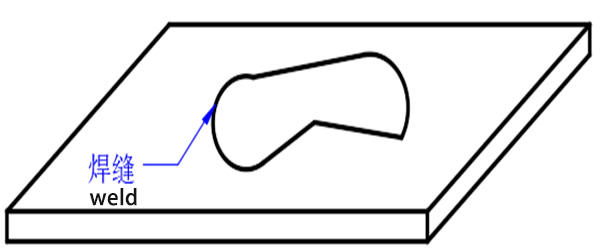

2. I-flat ivaliwe i-weld yesithombe

Njengoba kukhonjisiwe kuMdwebo 4, umumo we-weld womkhiqizo uyindilinga eyisiyingi, umumo wendiza ohlanganisa amazwe amaningi, umumo wendiza onezigaba eziningi nokunye okuvaliwe.Ifomu elihlanganyelwe lingaba yi-butt joint, i-lap joint, i-welding eyeqayo nokunye.Kulolu hlobo lomkhiqizo, kungcono ukusebenzisa imodi yegesi evikelayo e-coaxial eboniswe kuMfanekiso 2.

Ukukhethwa kwegesi evikelayo kuthinta ngqo ikhwalithi yokushisela, ukusebenza kahle kanye nezindleko zokukhiqiza, kodwa ngenxa yokuhlukahluka kwezinto zokuthungatha, inqubo yokufaka i-welding, ukukhethwa kwegesi yokushisela kuyinkimbinkimbi, kudinga ukucatshangelwa okuphelele kwezinto zokushisela, indlela yokushisela. , isikhundla Welding, kanye nezidingo umphumela Welding, ngokusebenzisa izivivinyo Welding ukukhetha ezifanele kakhulu igesi Welding, Welding ukuze kuzuzwe imiphumela engcono.

Umthombo: Welding Technology

Isikhathi sokuthumela: Sep-02-2021