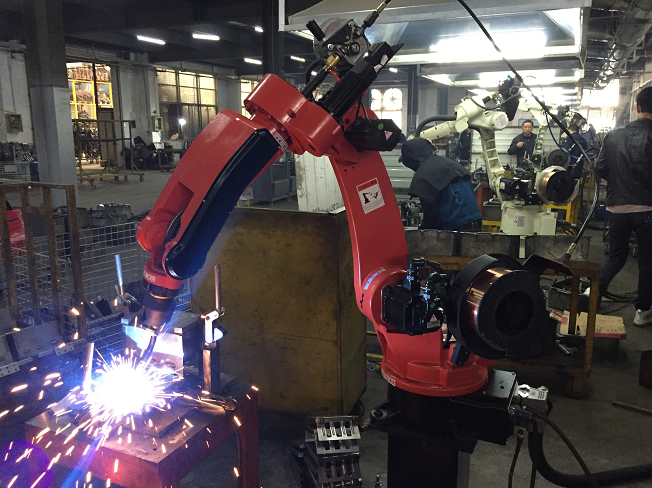

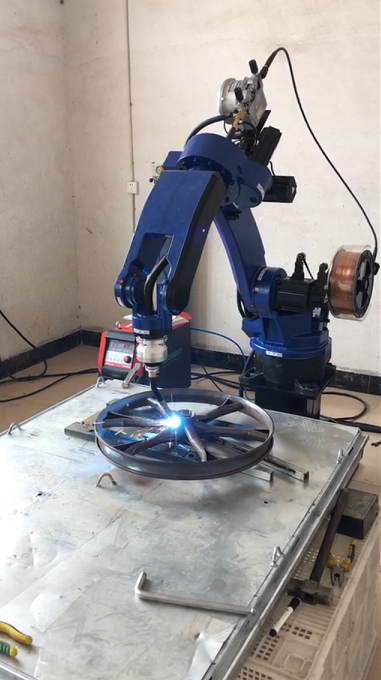

Kulesi sigaba, amarobhothi okushisela asetshenziswe kabanzi ekwakhiweni kwezimoto, ukushiselwa kukagesi kwe-chassis, imidwebo yamathambo esihlalo, ama-slide rails, ama-mufflers kanye nama-torque converter awo, njll.sebenzisa.

Izinkampani zezimoto zinqume ukuhlomisa ukushisela njengenjwayelo, zisebenzisa lolu hlobo lobuchwepheshe ukuthuthukisa ikhwalithi yokushisela ugesi, futhi zizame nokukusebenzisa esikhundleni sokusebenza kwe-arc welding.Isikhathi esingaphakathi komugqa omfushane sibuye sincishiswe kakhulu.Muva nje kukhishwe irobhothi lokushisela eline-aspect ratio ephansi, elisetshenziselwa ukushisela izingxenye ezingezansi zomzimba ngokushisela ngogesi.Lolu hlobo lwerobhothi elihlakaniphile lokushisela lingahlanganiswa namarobhothi amade ukuze akhiqize futhi acubungule indawo engaphezulu yomzimba, ngaleyo ndlela kuncishiswe ubude bawo wonke umugqa wokukhiqiza we-welding kagesi.

Iningi lezingxenye ze-chassis yemoto njenge-axle yangemuva, uhlaka olungaphansi, ingalo ye-crank, isistimu yokumiswa, i-shock absorber, njll. ekhiqizwayo kufanele ibe izingxenye zokuphepha ezibuswa indlela yokushisela ye-MIG.Kungu-1.5 ~ 4mm.Isihluthulelo se-welding kagesi silawulwa ama-lap joints nama-fillet joints.Izinga le-welding kagesi kanye ne-welding liphezulu kakhulu, futhi izinga layo liyingozi kusici sokuphepha semoto.Ngemuva kokusetshenziswa kwe-robot yokushisela, ukubukeka kanye nekhwalithi ebalulekile ye-weldment kuthuthukiswa nakakhulu, futhi ukuthembeka kwekhwalithi kuqinisekiswa, ukusebenza kahle kwabasebenzi kuyancishiswa, futhi indawo yabasebenzi iyathuthukiswa.

Isikhathi sokuthumela: Mar-21-2022