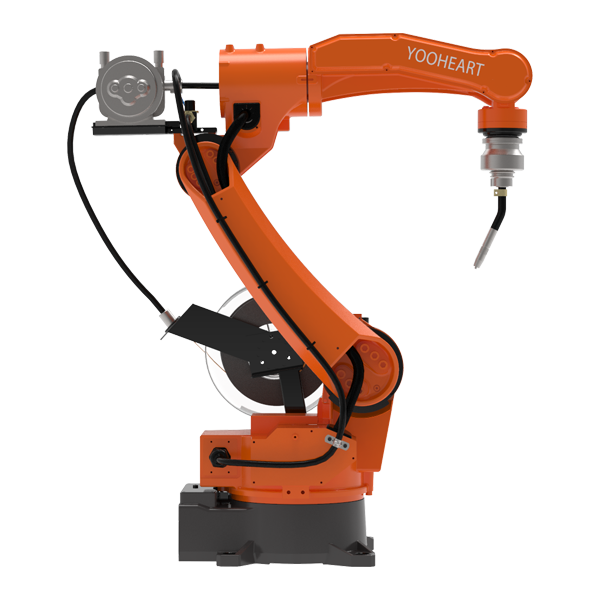

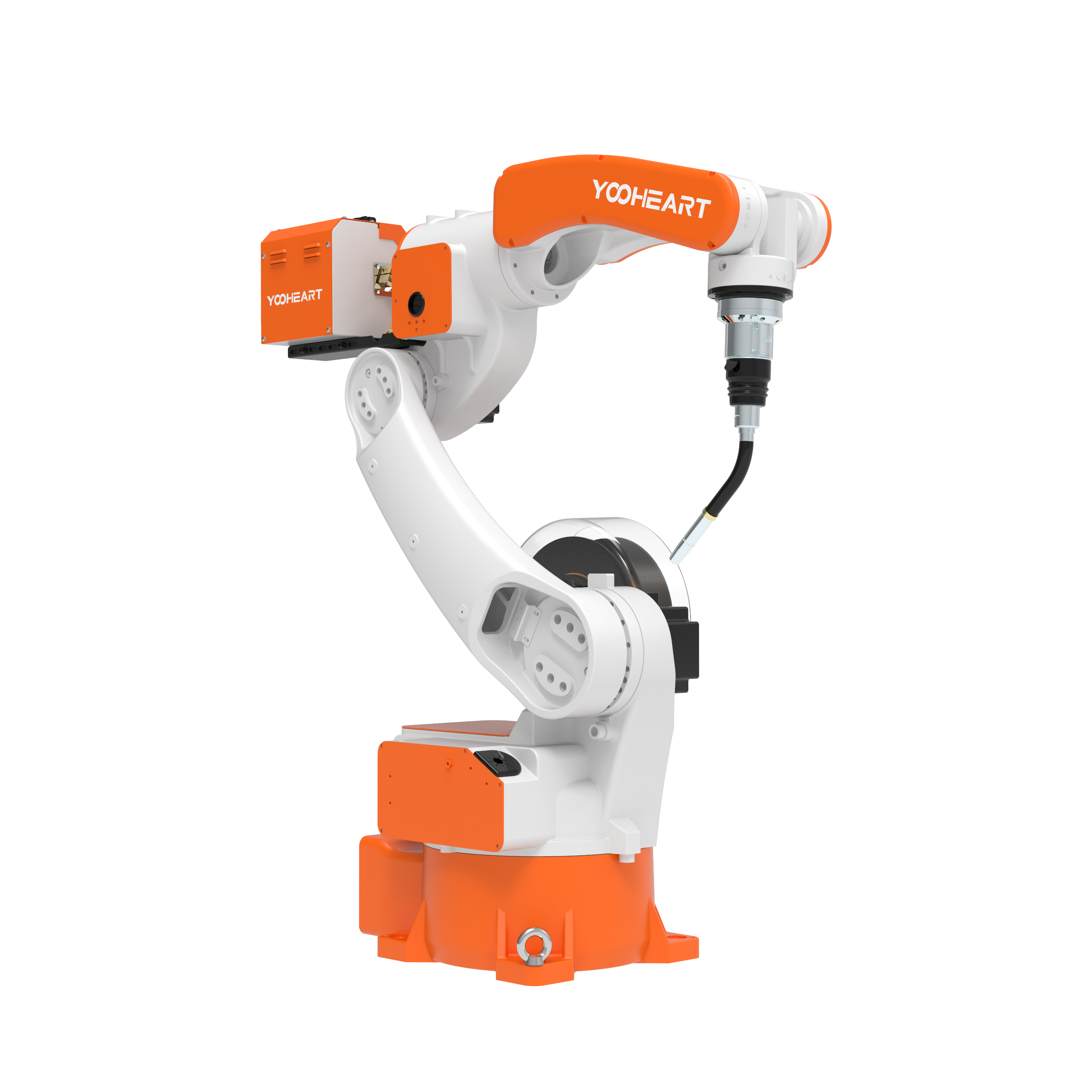

Irobhothi lokushisela i-TIG

Isingeniso Somkhiqizo

I-GTAW isetshenziswa kakhulu ukushisela izingxenye ezincane zensimbi engagqwali nezinsimbi ezingenayo insimbi njenge-aluminium, i-magnesium, nama-alloys ethusi. Inqubo inika isisebenzisi ukulawula okukhulu kokushisela kunezinqubo eziqhudelanayo ezifana nokushisela i-arc yensimbi evikelekile kanye ne-gas metal arc welding, okuvumela ukushisela okuqinile, kwekhwalithi ephezulu. Kodwa-ke, i-GTAW iyinkimbinkimbi kakhulu futhi inzima ukuyiqonda, futhi ngaphezu kwalokho, ihamba kancane kakhulu kunamanye amasu amaningi okushisela. Inqubo ehlobene, i-plasma arc welding, isebenzisa ithoshi yokushisela ehluke kancane ukuze idale i-arc ye-welding egxile kakhulu futhi ngenxa yalokho ivame ukuzenzekelayo.

I-Yunhua isebenzisa izinyathelo ezikhethekile zokuvimbela ngesikhathi sokushiswa kwe-TIG, futhi kuyoba nebhukwana elikhethekile lomqhubi, kuphela uma opharetha engakwazi ukulandela imanuwali, futhi asebenzise izikhathi eziningana, angakwazi ukuqonda ngokushesha okukhulu.

I-PARAMETER YOMKHIQIZO NEMINININGWANE

| Imodeli | I-WSM-315R | I-WSM-400R | I-WSM-500R | |

| Ilinganiswe nge-voltage / imvamisa | Izigaba ezintathu380V (+/-)10% 50Hz | |||

| Umthamo wokufaka olinganiselwe (KVA) | 11.2 | 17.1 | 23.7 | |

| Okokufaka okulinganiselwe okwamanje(A) | 17 | 26 | 36 | |

| Isilinganiso sokusimama komthwalo (%) | 60 | 60 | 60 | |

| DC kanye namanje njalo | I-Welding Curren (A) | 5~315 | 5-400 | 5-500 |

| I-DC pulse | Inani eliphakeme lamanje (A) | 5~315 | 5-400 | 5-500 |

| Isisekelo samanje (A) | 5~315 | 5-400 | 5-500 | |

| Umsebenzi we-Pulse (%) | 1~100 | 1~100 | 1~100 | |

| Imvamisa ye-Pulse (Hz) | 0.2~20 | |||

| I-TIG | I-arc eqala manje (A) | 10-160 | 10-160 | 10-160 |

| I-arc stop current (A) | 5~315 | 5-400 | 5-500 | |

| Isikhathi sokwanda kwamanje (S) | 0.1~10 | |||

| Isikhathi sokuncipha kwamanje (S) | 0.1~15 | |||

| Isikhathi sangaphambi kokugeleza (S) | 0.1~15 | |||

| Isikhathi sokumisa igesi (S) | 0.1~20 | |||

| Isitayela sokusebenza se-arc yokumisa yamanje | Izinyathelo ezimbili, Izinyathelo ezine | |||

| Isitayela se-arc somshayeli we-TIG | Isiqephu se-HF | |||

| Isandla se-arc Welding Welding yamanje | 30~315 | 40-400 | 50~500 | |

| Imodi yokupholisa | Ukupholisa amanzi | |||

| Ibanga lokuvikela igobolondo | 1P2S | |||

| Ibanga le-insulation | H/B | |||

Isicelo

UMTHETHO 1

Isingeniso

Irobhothi elishisela i-tig le-Electric Iron

Inqubo yokushisela i-Pulse Tig ye-fish scale weld seam.

UMTHETHO 2

Isingeniso

Irobhothi lokushisela i-tig lensimbi engagqwali

I-Tig arc welding yokushisela ipayipi eliyisikwele.

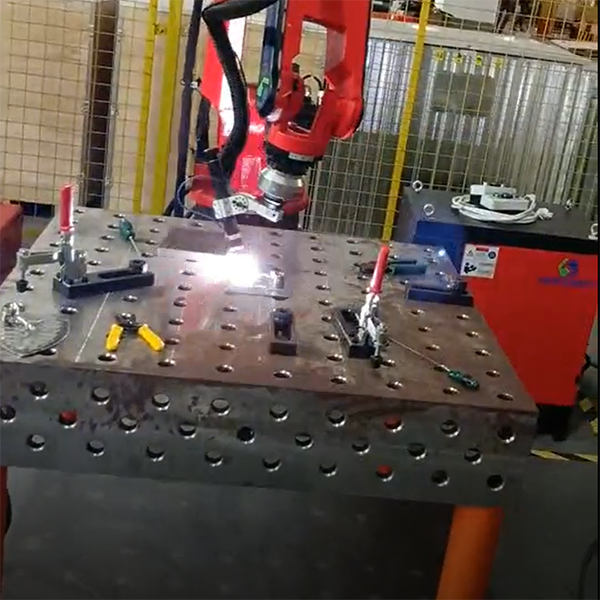

UMFANEKISO 3

Isingeniso

Imingcele ye-TIG welding welding

Ukusebenza kwe-Pulse Tig welding. Ubukhulu: 1.5mm, iphutha lokulinganisa: ±0.2mm.

UKUDILIVA NOKUTHUMELA

I-Yunhua inganikeza amakhasimende ngemibandela ehlukene yokulethwa. Amakhasimende angakhetha ukuhambisa ngendlela ngolwandle noma ngomoya ngokuya ngokuphuthuma kuqala. Amakesi okupakisha amarobhothi e-YOO HEART angahlangabezana nezidingo zempahla yolwandle nomoya. Sizolungisa wonke amafayela afana ne-PL, isitifiketi somsuka, i-invoyisi namanye amafayela. Kukhona isisebenzi umsebenzi waso oyinhloko uwukuqinisekisa ukuthi wonke amarobhothi angalethwa echwebeni lamakhasimende ngaphandle kokuphazamiseka ezinsukwini ezingama-40 zokusebenza.

Ngemva kwenkonzo yokuthengisa

Wonke amakhasimende kufanele azi irobhothi le-YOO HEART ngaphambi kokuthi alithenge. Uma amakhasimende esenerobhothi elilodwa le-YOO HEART, isisebenzi sawo sizoba nezinsuku ezingu-3-5 zokuqeqeshwa kwamahhala efektri ye-YOO HEART. Kuzoba neqembu le-Wechat noma iqembu le-WhatsApp, ochwepheshe bethu abanomthwalo wemfanelo emva kwesevisi yokudayiswa, ugesi, i-hard ware, isofthiwe, njll, bazobe bekhona. Uma inkinga eyodwa yenzeka kabili, uchwepheshe wethu uzoya enkampanini yamakhasimende ukuze axazulule inkinga.

I-FQA

Q1. Yiziphi izinhlelo zokusebenza ezingcono kakhulu ze-robotic TIG welding system?

Izicelo ze-A.Ivolumu ephezulu, ezinhlobonhlobo eziphansi zifaneleka kahle ukushisela i-robotic; kodwa-ke, ivolumu ephansi, izinhlelo zokusebenza ezihlukene zingase zisebenze uma zisetshenziswa ngendlela efanele. Izinkampani kuzodingeka zicabangele izindleko ezengeziwe zamathuluzi ukuze zinqume ukuthi uhlelo lokushisela lwerobhothi lusengakwazi yini ukunikeza imbuyiselo eqinile ekutshalweni kwezimali kokuqala. Ngokuqondene ne-TIG welding, isicelo esingcono kakhulu izingcezu ezincane nensimbi.

Q2. Iyiphi esebenzisa kangcono? I-HF TIG welding noma i-Lift TIG welding?

A. Inketho edume kakhulu nengcono kakhulu ukusebenzisa i-High Frequency start ekhiqiza i-arc yefrikhwensi ephezulu ekwazi ukwenza i-ionizing emoyeni futhi ivale igebe phakathi kwephoyinti le-tungsten nomsebenzi. Ukuqala kwe-High Frequency kuyindlela yokuthintwa futhi kudala ukungcola ngaphandle kwalapho i-tungsten isilolwe kakhulu noma i-amperage ijikiswe yaba phezulu kakhulu ekuqaleni. Kuyisinqumo esihle kakhulu sokushisela i-aluminium, futhi ukuphela kwesinqumo esamukelekayo. Ngaphandle kokuthi udinga ukushisela i-Aluminium, akudingeki ukuthi ube nesiqalo se-High Frequency, kodwa kuhle ukuthi ushise i-AC noma i-DC uma unenketho.

Q3. Ingabe irobhothi le-YOO HEART TIG elishiselayo lingasebenzisa isigcwalisi?

A.Yebo, singabanye abambalwa abangasebenzisa i-filler uma i-TIG ishisela. Abahlinzeki abaningi emakethe bangakutshela ukuthi amarobhothi abo angasetshenziselwa ukushisela i-TIG, ungambuza imibuzo enjengokuthi: ukuhlunga kanjani i-HF?, Ingabe irobhothi lakho lingasetshenziselwa ukushisela kwe-TIG nge-filler?

Q4. Indlela yokusetha umthombo wamandla uma usebenzisa i-TIG welding?

A. Umshini wakho wokushisela kufanele usethelwe ku-DCEN (Direct current electrode negative) owaziwa nangokuthi i-polarity eqondile yanoma yimuphi ucezu lomsebenzi odinga ukushiselwa ngaphandle uma impahla iyi-aluminium noma i-magnesium. Imvamisa ephezulu isethwe ukuthi iqale etholakala yakhiwe namuhla ngama-inverter. Ukugeleza kokuthunyelwe kufanele kusethwe okungenani ubuncane bemizuzwana eyi-10. Uma i-A/C ikhona isethelwa kusilungiselelo esizenzakalelayo esiqondana ne-DCEN. Setha isixhumi nokushintsha kwe-amperage kuzilungiselelo zesilawuli kude. Uma into edinga ukushiselwa i-aluminium polarity kufanele isethelwe ku-A/C, ibhalansi ye-A/C kufanele isethelwe cishe ku-7 futhi ukunikezwa kwefrikhwensi ephezulu kufanele kuqhubeke.

Q5. Indlela yokusetha igesi yesihlangu ngesikhathi sokushisela i-TIG?

A. I-TIG yokushisela isebenzisa igesi engasebenzi ukuze ivikele indawo yokushisela ekungcoleni. Ngakho-ke le gesi engasebenzi nayo ibizwa ngokuthi igesi evikelayo. Kuzo zonke izimo kufanele kube i-argon futhi kungabikho enye igesi ye-inert njenge-neon noma i-xenon njll ikakhulukazi uma ukushiselwa kwe-TIG kuzokwenziwa. Kufanele isethwe cishe ngo-15 cfh. Ukuze uthole i-aluminium yokushisela kuphela ungasebenzisa inhlanganisela engu-50/50 ye-argon ne-helium.